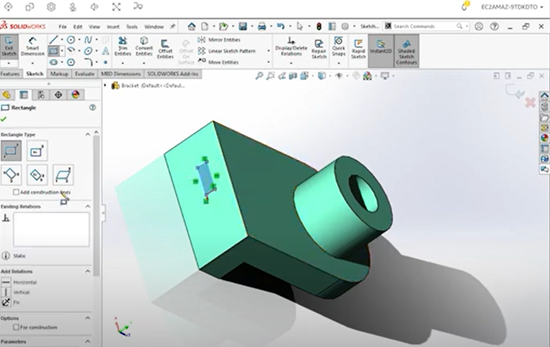

Considering the leap to cloud-based CAD and PDM solutions? A move to platforms like SolidWorks 3D CAD in the cloud paves the way for unmatched flexibility. Imagine accessing intricate engineering data from anywhere at any time. And, the benefits don’t end there. In fact, Cloud solutions amplify collaboration, heighten security measures, streamline IT processes, and scale with ease. While there are merits to on-site SolidWorks, adopting SolidWorks PDM in the cloud and solutions like virtual CAD (vCAD) are the future. Here’s why.

The Historic Approach To Accessing Design Files Remotely

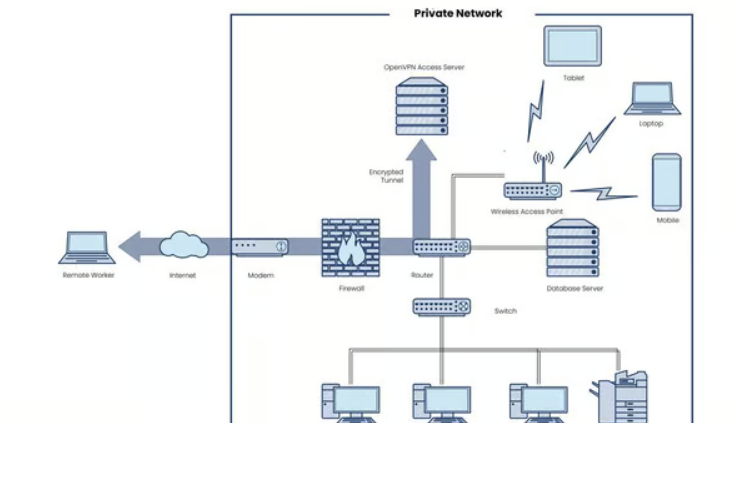

Today, many companies enjoy the luxury of design teams scattered globally, adding flexibility and quicker product rollouts. However, traditional on-site CAD and PDM methods typically rely on VPNs and WAN services. These are primarily designed for basic data and not graphics-heavy CAD applications. Ultimately, if you’re still using the VPN/WAN method, you’ll eventually notice inefficient performance. In fact, these global teams are left at a disadvantage if they don’t have an efficient means to store and collaborate on extensive CAD files. This capability isn’t fully supported by VPNs or conventional on-site storage.

As our blog post highlights, these systems weren’t designed with such heavy-duty operations in mind. Moreover, this outdated reliance can become a bottleneck, hampering creativity, and slowing down product development cycles. Global teams need a solution that supports real-time collaboration on CAD files, regardless of their size, without sacrificing performance or security.

Why Global Design Teams Need SolidWorks Cloud PDM

But, these days, physical limitations are no longer a constraint. In fact, SolidWorks 3D CAD in the cloud epitomizes this shift and caters to the needs of modern engineers and designers. As globalization drives teams to span remote workspaces (or even continents), the need for cloud solutions becomes even more pressing.

Now, the world is a business’s playground and they leverage talent from every corner of the globe. However, with this global approach come challenges in communication, data sharing, and real-time collaboration. And, businesses can make use of the tools available to support this, like SolidWorks Cloud PDM and CAD in the cloud (virtual CAD).

What Is Virtual CAD (vCAD)

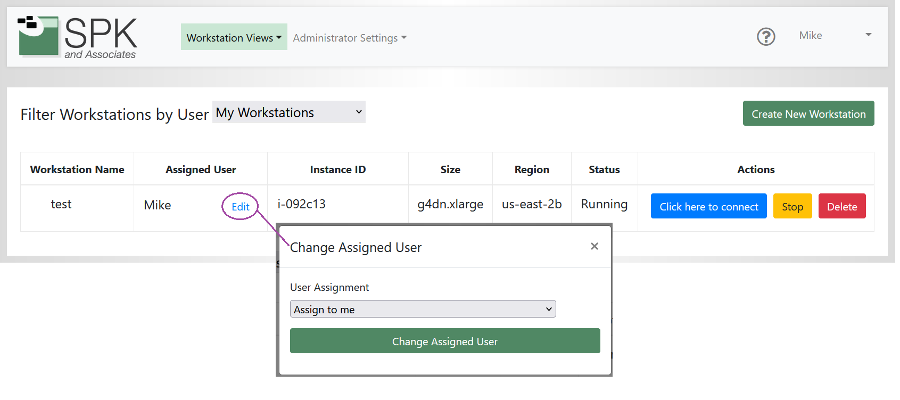

SPK foresaw the paradigm shift towards remote designs and rose to the occasion with its SolidWorks cloud PDM and CAD infrastructure. Coupled with a Virtual CAD Workstation, design teams now have a potent tool that caters to the nuances of distributed design. This solution doesn’t just simplify your CAD infrastructure but offers immediate ROI and a significant boost in productivity.

For design firms, the transition to this cloud-based solution means more than just convenience. It’s a significant step toward optimizing costs, boosting productivity, and ensuring they remain competitive in an ever-evolving market. As showcased in this case study, the tangible benefits of vCAD are impossible to ignore.

4 Advantages of SolidWorks Cloud PDM

Cloud storage, especially solutions like vCAD, is stepping up to cater to the complexities of multi-site CAD collaboration.

- Enhanced Collaboration: Engineers no longer work in silos but seamlessly share and collaborate. With platforms like SolidWorks cloud PDM and vCAD, teams attain efficient CAD collaboration. Essential files are quickly accessible, with active files cached locally, ensuring rapidity and efficiency.

- Secure Transfers: Every design is precious. Guaranteeing safe and encrypted transfers, especially of extensive CAD files, is non-negotiable. With cloud solutions like vCAD, transfers are not only faster but also more secure than many traditional data centers.

- IT Simplification: The diverse and aged IT infrastructure is both a financial and functional burden. The cloud storage systems like vCAD consolidate these complexities into a streamlined, cost-effective platform, as outlined in our definitive guide to accelerating product delivery with vCAD.

- Scalability: With SolidWorks Cloud PDM and vCAD, you’re not confined by the limitations of physical storage. The global file system ensures virtually limitless storage and unmatched performance, regardless of the number of locations.

Next Steps

vCAD represents the next step in efficiency, collaboration, and cost-saving. From streamlining product design to cutting down on engineering licensing fees, the benefits are tangible and transformative. Why tether your team to the constraints of the past when solutions like vCAD can improve your operations now?

SPK are well positioned to support your PDM in the cloud. We have deep expertise in the application and cloud infrastructure. That means we can support you to quickly identify performance bottlenecks and troubleshoot issues unique to your architecture.

- Contact SPK and Associates to see how we can help your organization with SolidWorks PDM in the Cloud, and virtual CAD solutions.

- Read our White Papers and Case Studies for examples of how SPK leverages technology to accelerate engineering for our clients.

- Check out our blogs to stay informed on product development and engineering efficiency topics.