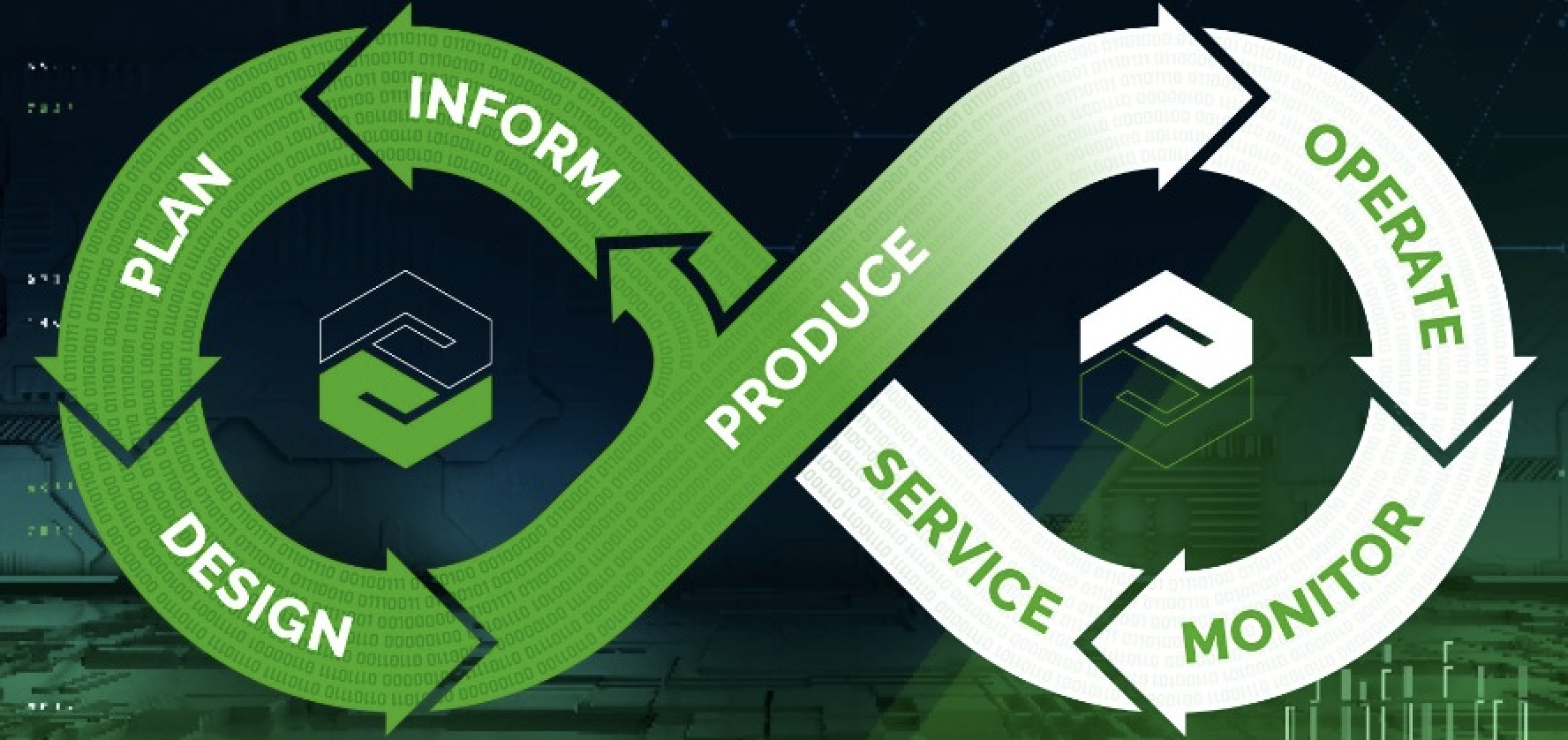

Modern product development depends on speed, traceability, and collaboration, yet many enterprises still operate with disconnected systems. This fragmentation makes it difficult to deliver high-quality, compliant products on time. A connected digital thread changes this. By connecting data across the entire product lifecycle, organizations gain real-time insight that drives better decisions. Let’s explore why integration is essential for digital thread success and how integration tools like OpsHub enable true lifecycle continuity by connecting platforms.

Why Enterprises Are Implementing Digital Threads

A digital thread is a strategic capability for organizations competing in fast-moving, highly regulated markets. At its core, a digital thread creates a continuous flow of trusted data from concept to retirement. It connects people, processes, and systems so that every stakeholder works from the same source of truth.

With a mature digital thread, organizations can access data in real time, eliminate manual handoffs, improve collaboration, and eliminate risks. Data that was once underutilized becomes a strategic asset. The result is higher product quality, improved operational efficiency, and a faster time to market.

Components of a Digital Thread

The key systems that make up a digital thread are:

Computer-Aided Design (CAD)

CAD systems provide digital models used for visualization, simulation, and validation. These models serve as the foundation for downstream engineering and manufacturing activities.

Product Lifecycle Management (PLM)

PLM acts as the central nervous system of the digital thread. It manages product structures, configurations, changes, documentation, and approvals throughout the lifecycle.

Application Lifecycle Management (ALM)

ALM governs requirements, development, testing, and deployment. For software-driven products, ALM ensures alignment between functional needs and delivered capabilities.

Together, CAD, PLM, and ALM form the backbone of a comprehensive digital thread.

How Integration Powers a True Digital Thread

Effective digital threads depend on frictionless connectivity between siloed systems. Integration ensures that information flows seamlessly across departments and platforms. When organizations integrate ALM, PLM, DevOps, and project management environments, they can improve cross-functional efficiency and minimize inconsistencies. Integration transforms disconnected tools into a unified lifecycle ecosystem.

How OpsHub Enables Traceability with the Digital Thread

OpsHub Integration Manager (OIM) is an enterprise-grade data integration platform designed to support complex, large-scale digital thread initiatives. By connecting systems such as Codebeamer, Windchill, Jira, Azure DevOps, and dozens of others, OpsHub enables true lifecycle continuity.

OpsHub’s flexible deployment options support both on-premise and cloud environments, ensuring alignment with enterprise infrastructure strategies. Plus, its no-code, reusable configurations allow teams to scale integrations quickly without disrupting ongoing operations. In addition to this, OpsHub creates an uninterrupted data flow from requirements to release for easy compliance with regulations. Furthermore, it supports over 60 commercial, legacy, and custom connectors, enabling organizations to preserve existing investments while modernizing their ecosystems. Lastly, OpsHub always preserves relationships, hierarchies, and references between objects, ensuring 100% data accuracy. This prevents information loss and maintains context across systems.

Key Benefits of an Integrated Digital Thread

When utilizing OpsHub to connect your ALM and PLM tools like Codebeamer and Windchill with DevOps and Project management tools such as Azure and Jira, teams achieve measurable business value. Here are some advantages of using OpsHub:

Accelerated Innovation

Real-time collaboration and shared data environments enable rapid iteration, faster feedback, and shorter development cycles.

Improved Manufacturing Planning

Up-to-date design and planning data improve alignment between engineering and production, reducing errors and delays.

Fail-Safe Compliance

Complete traceability creates auditable records that simplify regulatory reporting and quality management.

Closed-Loop Quality

Integrated quality data enables early detection of issues and continuous process improvement.

Service Optimization

Accurate product and configuration data improve service planning, maintenance, and lifecycle support.

OpsHub for Traceability

Digital threads are transforming how organizations design, build, and deliver complex products. However, without strong integration, digital thread initiatives remain fragmented and fragile.

By enabling frictionless connectivity across ALM, PLM, DevOps, and enterprise systems, OpsHub provides the foundation for scalable, secure, and compliant digital threads. With OpsHub Integration Manager, organizations can break down silos, eliminate vendor lock-in, and create a unified data ecosystem. For enterprises ready to unlock the full potential of their product data, contact us about OpsHub.