In the tech space and beyond, modern buzz has all pointed to AI. While I love exploring new ideas, I am also quite a pragmatist. This past year, I’ve navigated through endless white papers, blogs, books, videos, social posts, and articles about AI. These detail how it will fix everything or break everything, replace every job or fail completely, take over the world or destroy the world. It’s either utopian or dystopian, depending on the day or author.

AI in Context

As I contemplate all this information about AI, and digest it in the context of real experiences I see at our clients, and in our own company, I have been considering the practical demands it places on all of us as leaders.

I am also viewing AI through a different lens these days. I recently read a paper that truly resonated with me, “AI as Normal Technology,” published by knightcolumbia.org. The authors don’t understate the transformative impact of AI, but they “view AI as a tool that we can and should remain in control of, and we argue that this goal does not require drastic policy interventions or technical breakthroughs. We do not think that viewing AI as a humanlike intelligence is currently accurate or useful for understanding its societal impacts, nor is it likely to be in our vision of the future.”

Therefore, my orientation is towards AI augmenting human (engineer) capability, not realistically replacing it.

To me, this means treating AI in engineering as a transformative tool, but a tool nevertheless. How do we, as engineering leaders, effectively integrate and use this tool in our teams and systems this next year? How do we measure and get appropriate business outcomes?

My company serves product and software teams, particularly those in regulated industries. My viewpoint is based on how AI affects the discipline of engineering and product release, with an emphasis on regulated teams. As Engineering leaders, what should we be doing with AI in our organizations in 2026?

AI for Product Engineering

Developing and releasing products is more complicated than software. There is plenty written about AI in software engineering these days. We see many success stories and some cautionary tales. However, there is less discussion about AI in the product engineering arena.

There are practical AI developments in the works, or released this past year, that are accelerating product engineering. The engineering leader should be prepared to actively consider these.

Our desired business outcomes fall within three categories:

- increase revenue

- minimize cost

- mitigate risk

Anything we consider trying with AI should produce a result in one of these categories. Otherwise, it’s not worth the time and cost. Eventually, the AI we experiment with must produce a positive ROI at scale.

AI Tools and Agents

There are many, many “AI applications” in the market right now that claim to solve every problem you have or might have. They fall into one of two categories: AI Knowledge Management and AI Agents. AI Knowledge Management tools aggregate data and information from disparate sources. Users can then ask natural language questions to get answers without needing to log into the tool. An AI agent is a software system that autonomously perceives its environment, reasons over goals and context, and takes actions—often across tools, data, and workflows—to achieve a defined outcome with minimal human intervention.

Despite the many general AI tools out there, I am more interested in the fact that most of the standard engineering applications – PLM, CAD, MES, Requirements and Test, DevOps, ALM – have already released the start of AI agentic capability in their software. Since these engineering apps already manage our information and workflows, I’d rather start with the AI capabilities in these proven (and validated) tools.

So, what AI capabilities are available right now in these engineering tools? And what should the engineering leader consider incorporating into the engineering workflows in 2026?

(Disclaimer: While I am not deeply familiar with every single engineering application out there, I expect that what is available in one tool is either available in the competition or will be in the coming year.)

AI in CAD

AI in CAD emerged gradually in 2025. The most immediate gains aren’t coming from radical new design concepts, but from eliminating friction in long-standing workflows. We now have the automation of 2D drawings from 3D models in platforms like Autodesk Fusion, SolidWorks, and Solid Edge. While this can’t replace the drafter’s work 100%, it can get them 60 to 80% of the way there, which sharply increases their productivity.

AI-driven inference of dimensions, tolerances, and views reduces manual effort and inconsistency, shrinking the gap between design intent and manufacturing reality. PTC Creo released this capability in 2025. This is less about speed for its own sake and more about reducing avoidable error and rework in environments where downstream mistakes are costly.

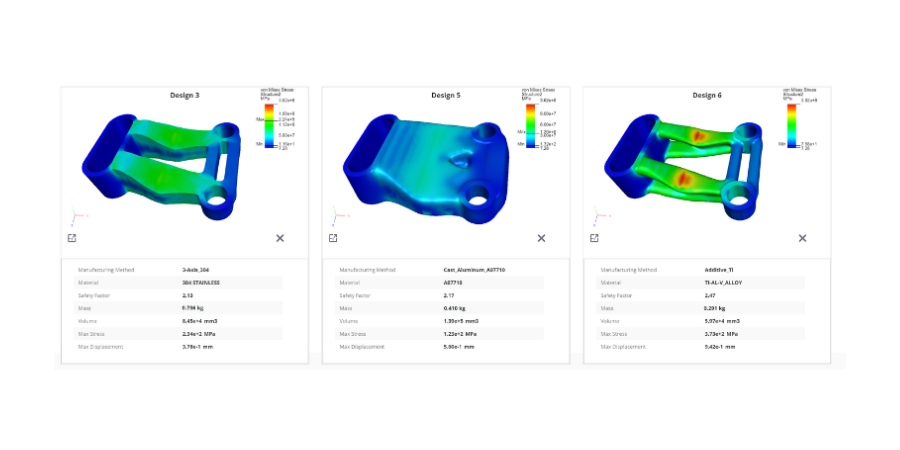

AI is also reshaping design exploration itself. Generative rendering and model optimization tools can now use computational methods to evaluate many design options against real constraints. This includes material properties, manufacturing methods, performance targets, and cost, shifting engineering work away from narrow, sequential iteration toward structured exploration. The competitive advantage doesn’t come from letting AI “design the product,” but from using it to surface tradeoffs earlier. Organizations that adapt their processes accordingly can converge on manufacturable, defensible designs faster.

AI in Requirements and Test Management

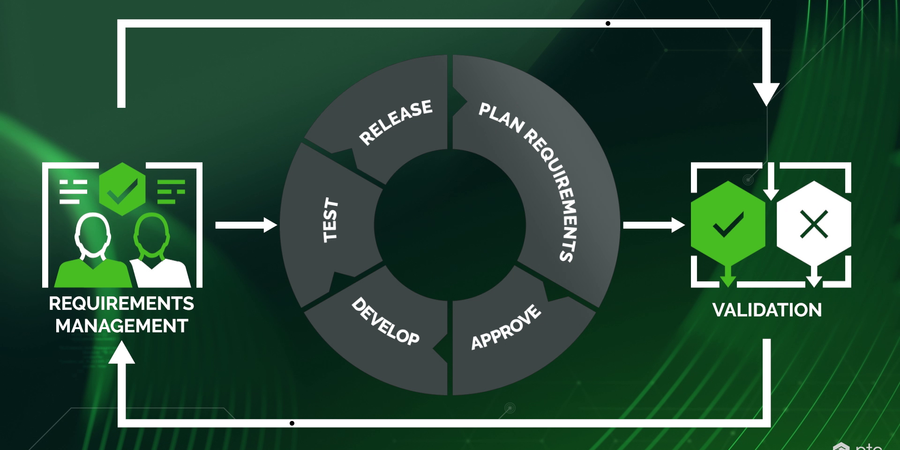

I’ve been watching this discipline of product development closely, as I could see quite early that there would be many exciting applications for AI, once incorporated into the apps. In tools like PTC Codebeamer 3.2 Requirements Assistant, AI assists with the quality and clarity of the requirements. Automated quality checks can now assess requirements against industry standards, flagging ambiguity, incompleteness, and structural issues early. This means checking before they propagate into design defects, test gaps, and regulatory risk. The Requirements Assistant addresses a long-standing reality in engineering organizations: requirements are often written under time pressure, reviewed inconsistently, and treated as static artifacts rather than living controls.

AI-powered rewrite suggestions and intuitive editing experiences help teams improve clarity, consistency, and testability without turning requirements management into a bottleneck. Organizations that integrate these capabilities into their workflows will see fewer downstream defects and tighter traceability. Those that simply enable the features without changing review habits and ownership models will miss the point entirely.

What we’re all waiting for, however, is the ability to have AI create test cases for each requirement, ensuring traceability. This capability is not available yet, but coming quite soon, I believe. This feature will be an enormous efficiency gain, removing manual, tedious work from the queue.

AI in PLM

Product Lifecycle Management is likely to be one of the most productive domains for applied AI as it matures. PLM is fundamentally about workflows, decisions, and institutional knowledge, which are all areas where AI agents can deliver immediate time savings and ensure quality. As AI capabilities emerge in the PLM applications, agents will become active participants in daily work. These agents will help engineers navigate complexity rather than manage it manually.

Already available are capabilities such as part reuse, classification, and document insight. AI-assisted search can surface similar or duplicate parts during design, reducing redundant creation and lowering long-term carrying and inventory costs. Part reuse has long been an elusive benefit of PLM. While the promise was there since the advent of PLM, it has been tricky to realize at scale. The benefit has relied on engineers properly classifying and attributing parts at creation. This has been a manual effort susceptible to error and avoidance. Classification agents can now infer part categories and attributes, streamlining rationalization efforts that have historically stalled due to this manual effort.

In addition, current PLM apps now use AI to unlock value trapped in PLM document vaults. Similar to ChatGPT or Claude, users can use natural language to summarize lengthy specifications or surface relevant knowledge to answer context-specific questions.

AI in MES

Manufacturing execution, lab, and shop-floor operations are a truly high-leverage domain for applied AI, because operations like these involve repetitive, data-rich, and tightly governed work.

Platforms like Tulip already use AI to collapse the distance between documentation and execution. AI-accelerated work instruction generation can ingest existing SOPs, PDFs, and checklists, extract key steps and imagery, and automatically produce interactive digital workflows. What historically took weeks of manual configuration can now be produced in a fraction of the time.

Beyond digitizing instructions, AI is now embedded into execution itself. Natural-language analytics lower the barrier to operational insight, allowing frontline leaders to query defects, downtime, or throughput without external BI tools. Pattern detection surfaces trends that would otherwise be buried in raw data, while embedded AI vision enables real-time quality checks—verifying parts, labels, and procedural steps before errors propagate.

On top of this, configurable AI agents can monitor operations continuously, flag anomalies, balance workloads, and trigger actions across connected systems. AI is no longer just analyzing operations after the fact. It is becoming part of how work is guided, validated, and optimized in real time.

AI in Engineering Knowledge Management

While engineering tools are offering natural-language access to their own data, this per-tool approach is fundamentally limited. It reinforces silos rather than breaking them. The real economic opportunity lies in a private, domain-tuned specific language model that spans the engineering lifecycle, providing a single conversational layer across requirements, design, test, manufacturing, and documentation. Without this unifying layer, NLP inside individual tools will remain a convenience feature, not a meaningful shift in how engineering organizations work.

SPK is starting to implement AI Engineering Knowledge Management solutions like this for our clients. We expect to see economic gains that translate directly to increased revenue, decreased product costs, and mitigated risk. This solution will decrease engineering licensing and training costs. It reduces friction for non-engineering users to gain access to important product information. The strategic advantage isn’t just efficiency; it’s lowering the cognitive and procedural barriers that prevent organizations from fully leveraging the data they already have.

What Are Your Next Steps?

As with any new feature, new AI capabilities that are available for your engineers will need to be highlighted. First, take the time to understand these AI features in your engineering applications. How do they work? How will they increase revenue, minimize cost, or mitigate risk? How robust and reliable are they? You will need champions within your team to experiment with the features. Create a small cross-functional team that is excited about the new technology.

After testing, you will need to work the agentic features into your existing SOPs and workflows. Your employees (including non-engineers) will need to be trained. If the features are included in a new version of the engineering software, the process changes can be included in your normal software upgrade procedure.

Most importantly, understand that there is a considerable amount of fear and trepidation surrounding AI for our teams. Some of this is because of the dystopian picture painted by some, or the claim that “AI will replace all jobs” by others.

Going back to my earlier comment about how I view AI “as normal technology” (although still transformative), I try to present new AI capabilities in this framework. AI introduces more automation. Automation has always disrupted workforces. Any new automation capacity requires a human, empathetic approach from team leaders. Understand who the new AI features will affect, and how those people will feel. Address their concerns, and have a plan as to how to retrain or develop new positions. Be transparent as to what is happening and what the results might be. If you follow these steps, your team will let go of dystopian worries and start unlocking the value of AI. For questions regarding how SPK can help your team implement AI solutions, reach out here.