An important part of creating any product intended for use in the medical field is that the manufacturer should have identified all of the risks involved in using the device, and have done their best to mitigate those risks before their product ever sees a patient. With this in mind, PTC bundled a Risk Management module as part of the Medical Device solution to be used with PTC Integrity Lifecycle Manager. In my last post, I discussed the Medical Device solution in general—today I am going to dive deeper into the Risk Management portion of this solution.

Risk Management, as defined in ISO 14971, among other things covers the following: Risk Analysis, Risk Evaluation, and Risk Control. Risk analysis consists of the following three steps:

- Determine the intended use and the characteristics related to the safety of the medical device.

- Identify the hazards of the medical device. These are an abstract view of what the risks may be for the patient.

- Estimate the potential outcome for each of the identified hazards.

One you have analyzed the risks associated with your new product, you need to perform an evaluation of the risks. Risk Evaluation consist of the following three items:

- Identify the potential sources of the hazards you identified in the phase above. Each of these potential sources would be considered a Risk.

- Determine the severity of each Risk as well as the probability of occurrence. This means you need to determine what could happen to the patient, as well as how likely it is for that outcome to occur.

- Based on that the severity and the probability of occurrence, you can then determine if the Risk is Acceptable, Unacceptable, or Needs Investigation.

Any risks that are determined to be either Unacceptable risks or risks that require further investigation, are subject to Risk Control. These risks can be controlled in the following manner:

- You first perform a risk control option analysis to if a given unacceptable or needs investigation risk can be controlled in any of the following three ways:

- Inherent safety by design. This is where you change the design of your product to reduce or eliminate the risk.

- A protective measure. This is where add a safety feature to the product to reduce the risk.

- Provide information for the safety of the user. This is where you would provide information about the specific risk, and how the customer should safely use the product.

- Once risk controls have been implemented, a residual risk evaluation is needed, it may be that the new reduced risks will still require risk control, or if new risks have been introduced as a result of the risk control measures implemented.

- Document risks arising from risk controls and the overall completeness of risk control.

Of course, once you have completed those three parts Risk Analysis, Risk Evaluation and Risk Control, you need to provide an evaluation of the overall residual risk acceptability before you can move forward with the product. All of this would be bound together in a Risk Management Report that can be signed off by the appropriate stakeholders.

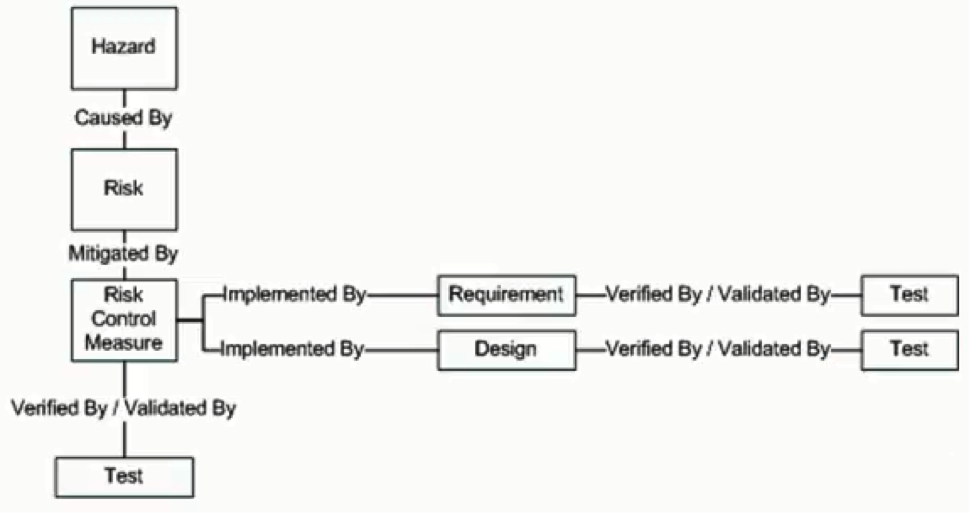

PTC, in order to implement this in the Medical Device solution for PTC Integrity Lifecycle Manager, chose to create three new document domains called Hazard, Risk, and Risk Control Measure to handle the Risk Analysis, Risk Evaluation, and Risk Control steps respectively. The diagram below explains how each of the three new domains are traced to each other and how they can connect into the Requirements Management portion of the Medical Device solution.

As you can see above, Hazards in the Hazard document are the result of the Risk Analysis step. These Hazards are traced via the “Caused By” trace relationship to Risk document. Within the Risk document you would perform your evaluation of each risk. Those risks that require mitigation are traced by the “Mitigated By” trace relationship to the Risk Control Measure document. These control measures are integrated into Requirement Specification, Design Specification, and Test Protocol via the “Implemented By” and “Verified/Validated By” trace relationships.

The Risk Management portion of the Medical Device solution provides the functionality you need to manage risk as part of your product development lifecycle. All the major pieces are covered off, and with it you can hit the ground running when it comes to developing safe new products efficiently.

Next Steps:

- Contact SPK and Associates to see how we can help your organization with our ALM, PLM, and Engineering Tools Support services.

- Read our White Papers & Case Studies for examples of how SPK leverages technology to advance engineering and business for our clients.