Creo is a powerful CAD tool that offers an immense range of capabilities. No matter how long you’ve been using it, there’s always room to level up. Whether you’re designing complex assemblies or optimizing for manufacturability, these best practices will help you improve model robustness and speed up your workflows. Here are 10 expert-level tips to sharpen your Creo skills and get more value from your design process.

Creo Best Practices for Better Modeling, Simulation, and Efficiency

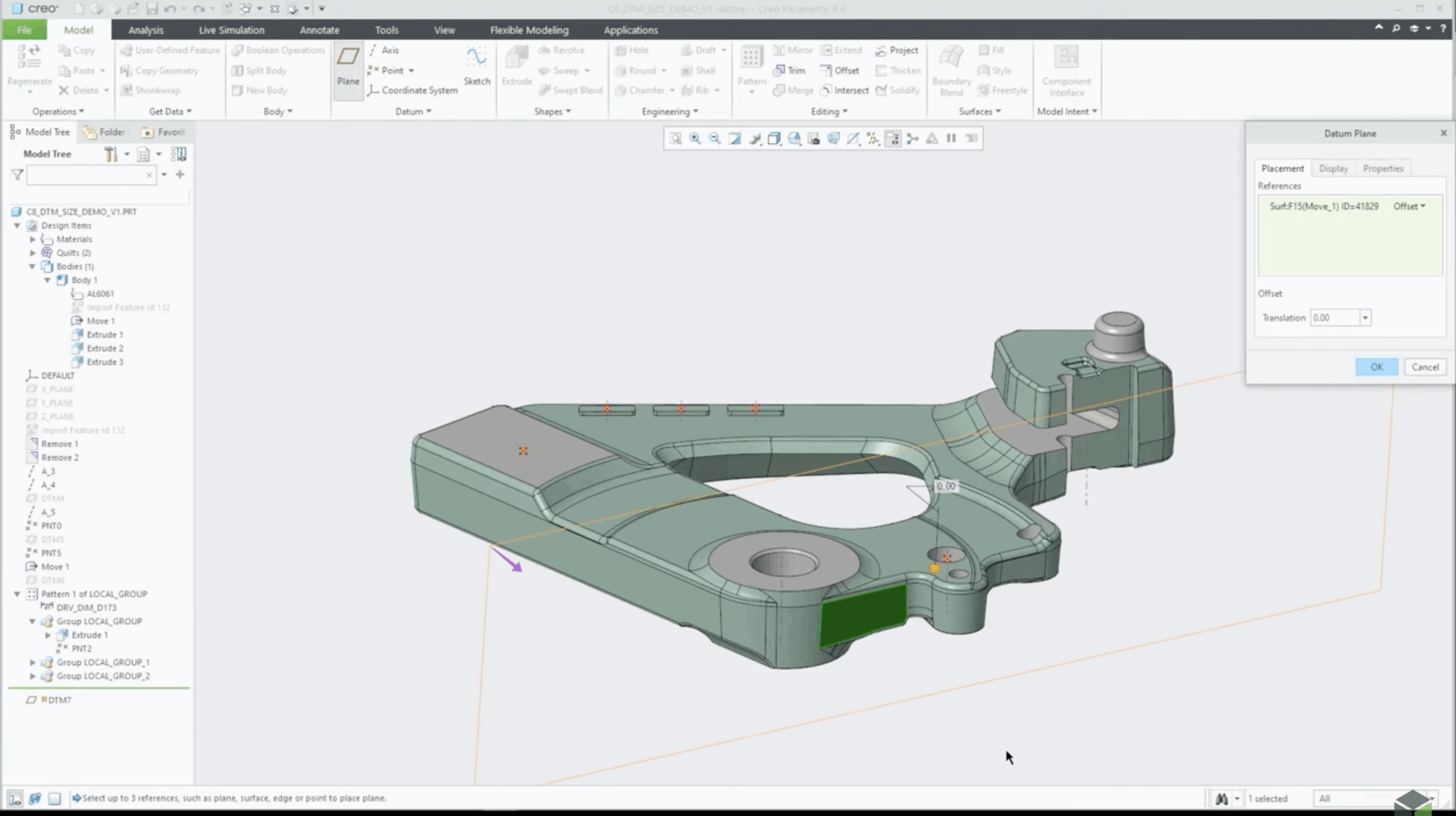

1. Master Reference Selection for Robust Models

Model failures in Creo often result from broken references. Avoid selecting edges that may disappear after rounds or chamfers. Instead, rely on stable references like datum planes and planar surfaces. Fewer, well-chosen references reduce feature interdependence and improve model stability.

2. Sequence Features Strategically

Rounds, chamfers, and drafts should typically be added last as they are more prone to regeneration errors. To prevent downstream feature failures, organize your model tree logically. Start with base geometry, add cuts and extrusions, then apply finishing features.

3. Simplify Sketches

Complicated sketches often result in fragile models. Break complex geometry into multiple, simpler features. Use construction lines, centerlines, and references to ensure constraints reflect your design intent. Simple sketches regenerate faster and are easier to modify later.

4. Use Datum Features to Drive Design Intent

Before creating geometry, build datum planes, axes, or points to define key control elements. For features that share a common reference, create a named datum so it’s easy to identify and reuse across your model. This improves predictability and supports future edits.

5. Leverage Mapkeys for Speed

Mapkeys are keyboard shortcuts that automate repetitive tasks like exiting Sketcher, erasing unused geometry, or showing model annotations. Incorporate them into your daily routine and you’ll dramatically increase your modeling speed while reducing mouse fatigue.

6. Enable and Use ModelCHECK

Creo’s diagnostic tools, like ModelCHECK, catch issues such as missing references, incomplete features, or geometry errors. Run it regularly to ensure your parts and assemblies regenerate without errors and meet company standards before release.

7. Use Generative Design and Simulation Early

Rather than optimizing manually, use Creo Generative Design to define constraints and let the software suggest optimized geometry. Pair it with Creo Simulation Live to evaluate performance instantly, without waiting for long meshing or solver times.

8. Implement Model-Based Definition (MBD)

Creo’s MBD tools allow you to embed dimensions, tolerances, and annotations directly into your 3D models. This eliminates the need for redundant 2D drawings and creates a single source of truth for manufacturing and inspection teams.

9. Master Surfacing Techniques

Use freestyle and ISDX (Interactive Surface Design Extension) for advanced surface creation. These tools help you model organic shapes and complex curvatures that can’t be achieved with standard parametric tools. This is perfect for consumer products, aerospace parts, and ergonomic designs.

10. Automate with Relations and Family Tables

Create smart parts that update automatically using relations and parameters. Use family tables to define product variants (e.g., fasteners, fittings) without duplicating models. This saves time and ensures consistency across product lines.

SPK and PTC: Better Together

At SPK and Associates, we help engineering teams unlock the full potential of Creo through consulting, training, and integration services. As a PTC partner, we’ve guided organizations in regulated industries on how to optimize product development workflows with tools like Creo, Windchill PLM, and ThingWorx. From feature strategy to enterprise-wide MBD adoption and simulation tool enablement, our experts work alongside your team to improve productivity and product quality.

Implementing Creo Best Practices

When combined with these best practices, Creo and SPK can help your team work smarter. You’ll be able to build more stable models, reduce design time, and communicate design intent more clearly. Whether you’re tackling surfacing, generative design, or MBD, these techniques will take your organization to the next level. Contact our experts if you want help assessing your current workflows, applying industry best practices, and achieving faster ROI on your PTC investments.