Accelerating product development is crucial for designers and manufacturers aiming to reduce time-to-market and cut costs. One of the most effective ways to achieve this is through prototyping. Creating digital and physical prototypes helps companies iterate quickly, optimize material usage, and enhance product quality. In this blog, we will explore the main components that drive rapid prototyping. Let’s uncover how tools like PTC’s Creo help optimize materials and costs.

Leveraging Rapid Prototyping Tools

Creo Simulation Live: Real-Time Design Validation

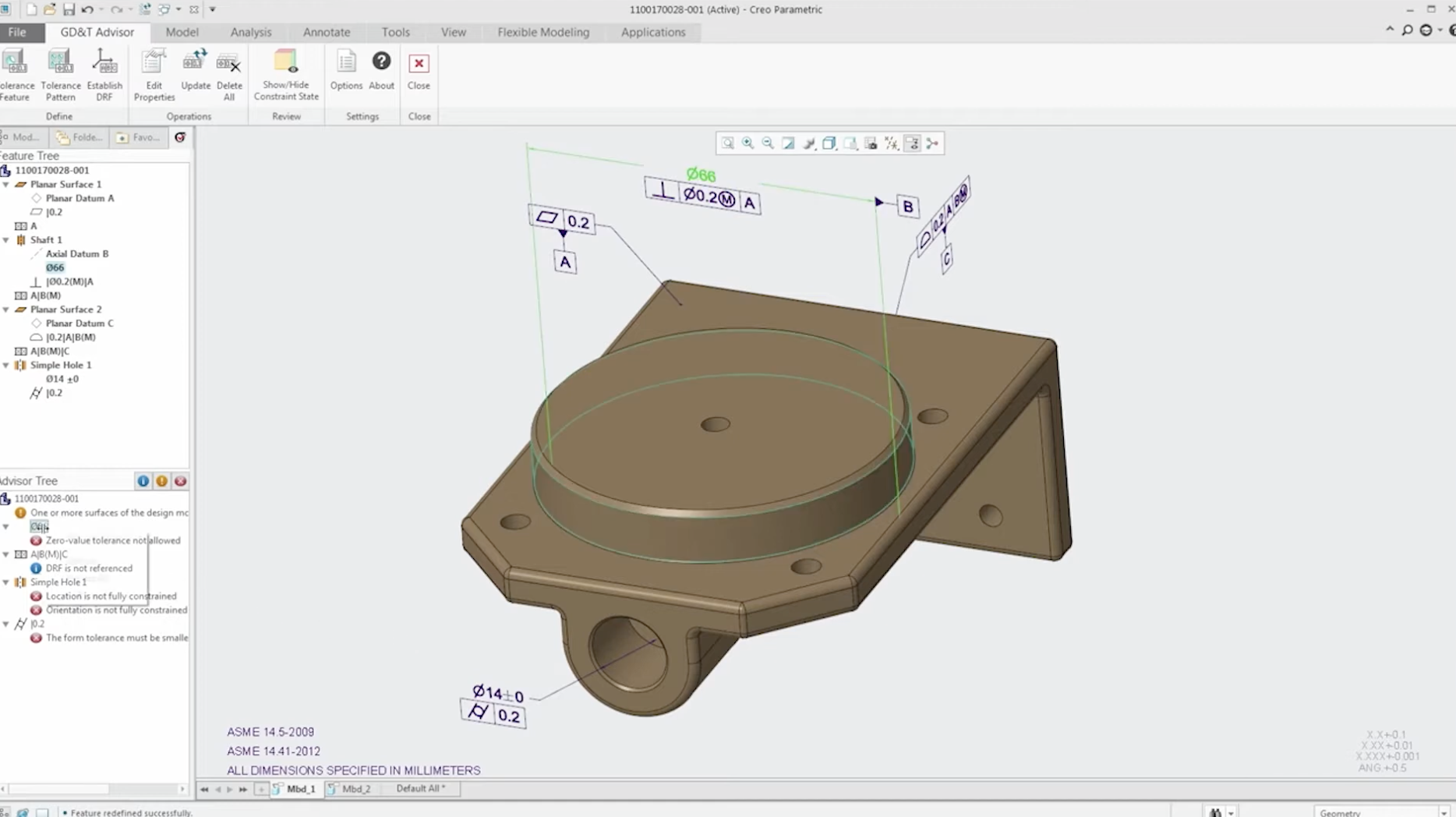

Faster prototyping starts with real-time simulation, and Creo Simulation Live (CSL) delivers exactly that. Traditional simulation tools require exporting models to separate environments. CSL works differently, performing structural, thermal, and fluid flow analyses directly within the Creo CAD workspace. Designers get immediate feedback as they adjust features, change material properties, or refine geometries. By integrating simulation into the design process, CSL enables engineers to identify and resolve design issues early. This helps prevent costly late-stage modifications. Additionally, it tests and validates design assumptions under real-world conditions without physical testing. This helps save material that would otherwise be used for physical prototypes. Furthermore, CSL shortens design cycles for engineers by allowing them to iterate more efficiently.

Creo Ansys Simulation

For a more comprehensive analysis, PTC offers Creo Ansys Simulation. This extension expands upon Creo’s capabilities, offering high-fidelity structural, thermal, and modal studies. PTC also offers Creo Ansys Simulation Advanced. This advanced version introduces features like multiphysics studies, nonlinear contact modeling, and nonlinear material behavior simulations. This type of testing is crucial for industries such as aerospace, automotive, and medical device manufacturing.

The Competitive Edge of Integrated Simulation

Integrated simulation:

- eliminates back-and-forth between CAD and simulation tools

- reduces reliance on expensive physical prototypes

- enhances confidence in product performance before production

Iterative Design with Creo

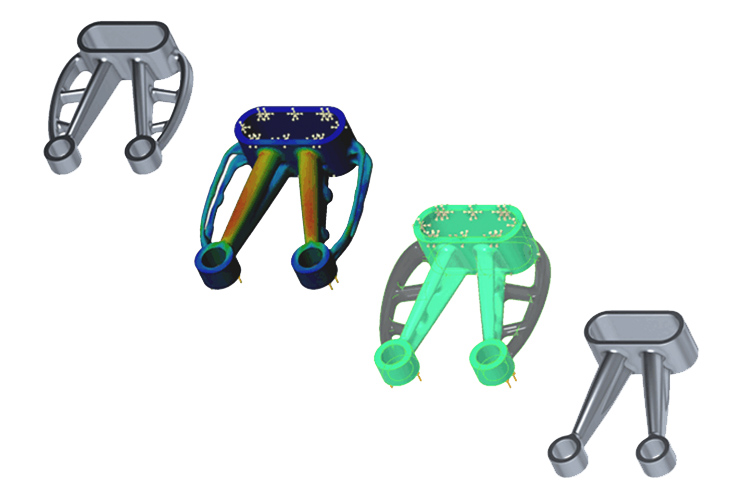

Iterative design is the backbone of rapid prototyping. It involves a cyclical process of prototyping, testing, analyzing, and refining a product to ensure continuous improvement. Creo Parametric supports this approach by offering advanced 3D modeling tools, generative design, and augmented reality (AR) visualization. These features ensure faster concept validation.

Key Stages of Iterative Design with Creo

Concept Design

In the concept design stage, engineers can use Creo’s flexible modeling and design exploration tools. These help users quickly generate multiple design alternatives. Generative design capabilities automatically produce optimized models based on user-defined goals, accelerating the selection of the best concept.

Prototyping & Testing

With Creo Simulation Live, engineers can refine their models in real-time. This reduces the reliance on physical prototypes and speeds up iterations.

Refinement & Finalization

The iterative process ensures that designs meet functional, performance, and cost requirements before they are manufactured. Creo’s advanced model-based definition (MBD) and smart connected design features enable seamless collaboration and accessible documentation for final production.

Benefits of Iterative Design in Creo

When engineers implement iterative design processes with Creo, they can create concepts quicker and reduce errors. They also enhance innovation through the continuous refinement that is encouraged. Overall, it results in products that should not have to be altered post-production which saves money and material.

Material Optimization: Balancing Cost, Performance, and Sustainability

We have touched on how Creo helps eliminate material waste but selecting and optimizing materials is also essential for cost-effective prototyping. Material optimization ensures that the right materials are used efficiently. They must balance strength, weight, durability, and environmental impact.

Key Aspects of Material Optimization

When choosing a material, you must identify your design needs. This includes analyzing mechanical, thermal, and durability requirements. Additionally, you should choose materials based on performance criteria. Ask yourself questions such as would a metal or polymer work better than a ceramic? Consider that you may also tailor your materials through heat treatment, alloying, or surface modifications.

Creo’s Role in Material Optimization

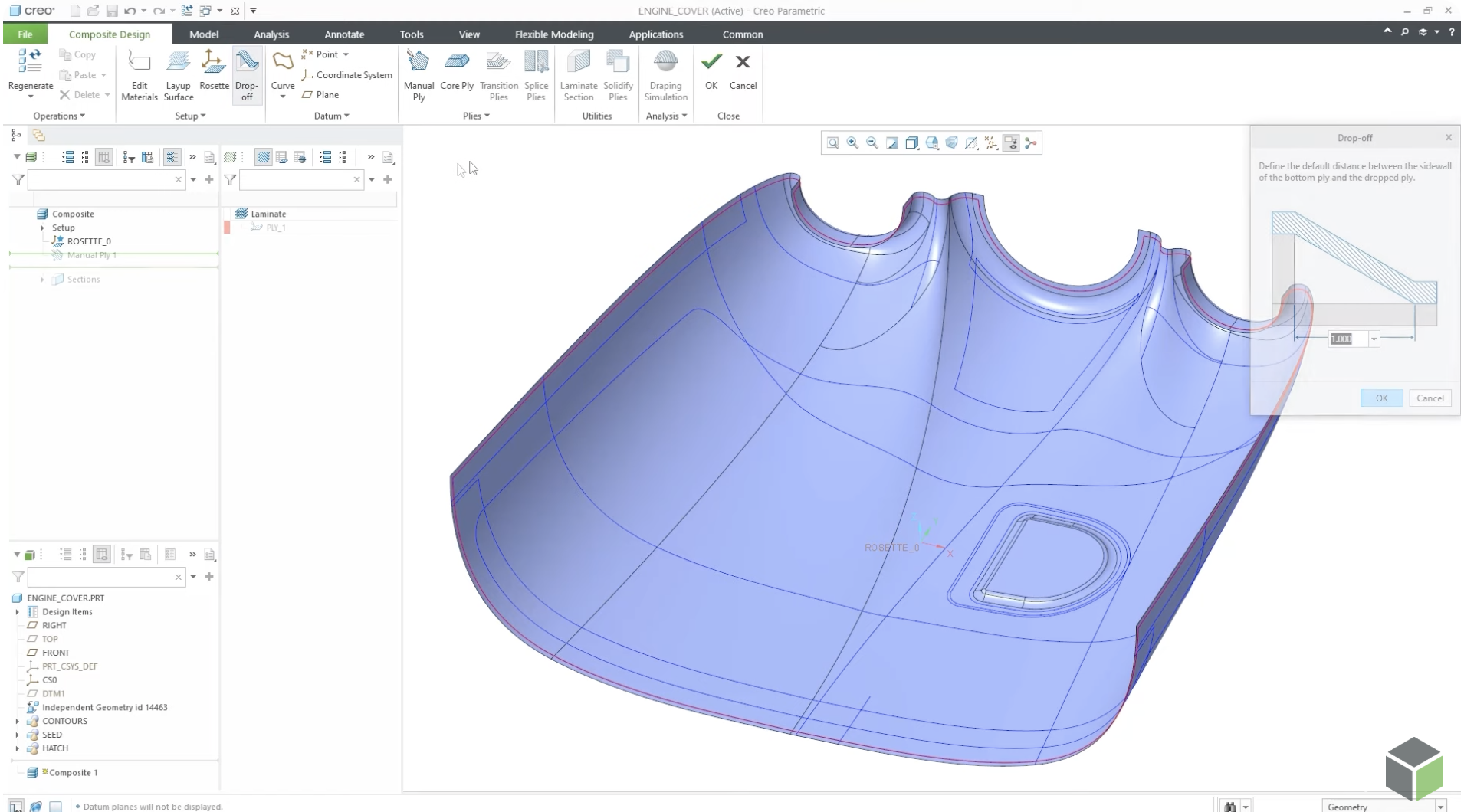

Creo Ansys Simulation Advanced supports nonlinear material modeling, allowing engineers to simulate realistic material deformations. Additionally, generative design in Creo suggests the most efficient material layouts for optimal weight and strength balance. Furthermore, Creo’s additive manufacturing tools enable the creation of lightweight, highly functional components with minimal material waste. Creo has also added the Creo Composite Design and Manufacturing Extension (CDM) as well as an advanced version (CDMA). These extensions provide composite support, allowing engineers to design with composite materials.

Benefits of Material Optimization

Material optimization results in benefits such as:

- Weight Reduction: Improves efficiency in aerospace, automotive, and other industries.

- Cost Savings: Minimizes material waste, reducing production expenses.

- Performance Enhancement: Ensures superior product functionality.

- Safety: Proper materials improve the durability of certain products such as medical devices.

- Sustainability: Reduces environmental impact by optimizing resource utilization.

Achieving Cost-Effective Rapid Prototyping with PTC Creo

By integrating rapid prototyping tools, iterative design processes, and material optimization, companies can significantly reduce their time-to-market and development costs. PTC Creo’s powerful simulation, modeling, and optimization capabilities make it an essential tool for product developers. Whether you’re refining machine designs, optimizing materials, or testing under extreme conditions, Creo provides the tools you need. If your business is ready to prototype smarter and bring products to market faster, contact us today. Explore how Creo can revolutionize prototyping, accelerating your product development!