The automotive industry is one of the largest industries in the world. The market is projected to grow to 2.95 trillion U.S. dollars this past year, causing a substantial amount of disruption. With this immense scale, comes many requirements manufacturers must follow. ISO standards are some of the most common compliance standards for the automotive industry. Let’s explore one particular standard and why it’s important to the automotive industry: ISO 9001.

What is ISO 9001?

ISO 9001 is the most widely used quality management standard in the world. The International Standard Organization (ISO) is the globally recognized creator of industry regulatory standards. ISO 9001 focuses on enhancing quality and satisfying client needs. Additionally, the standard offers guidance for successfully implementing a QMS. Although not mandatory, the standard is highly esteemed and may be implemented into law in the coming years.

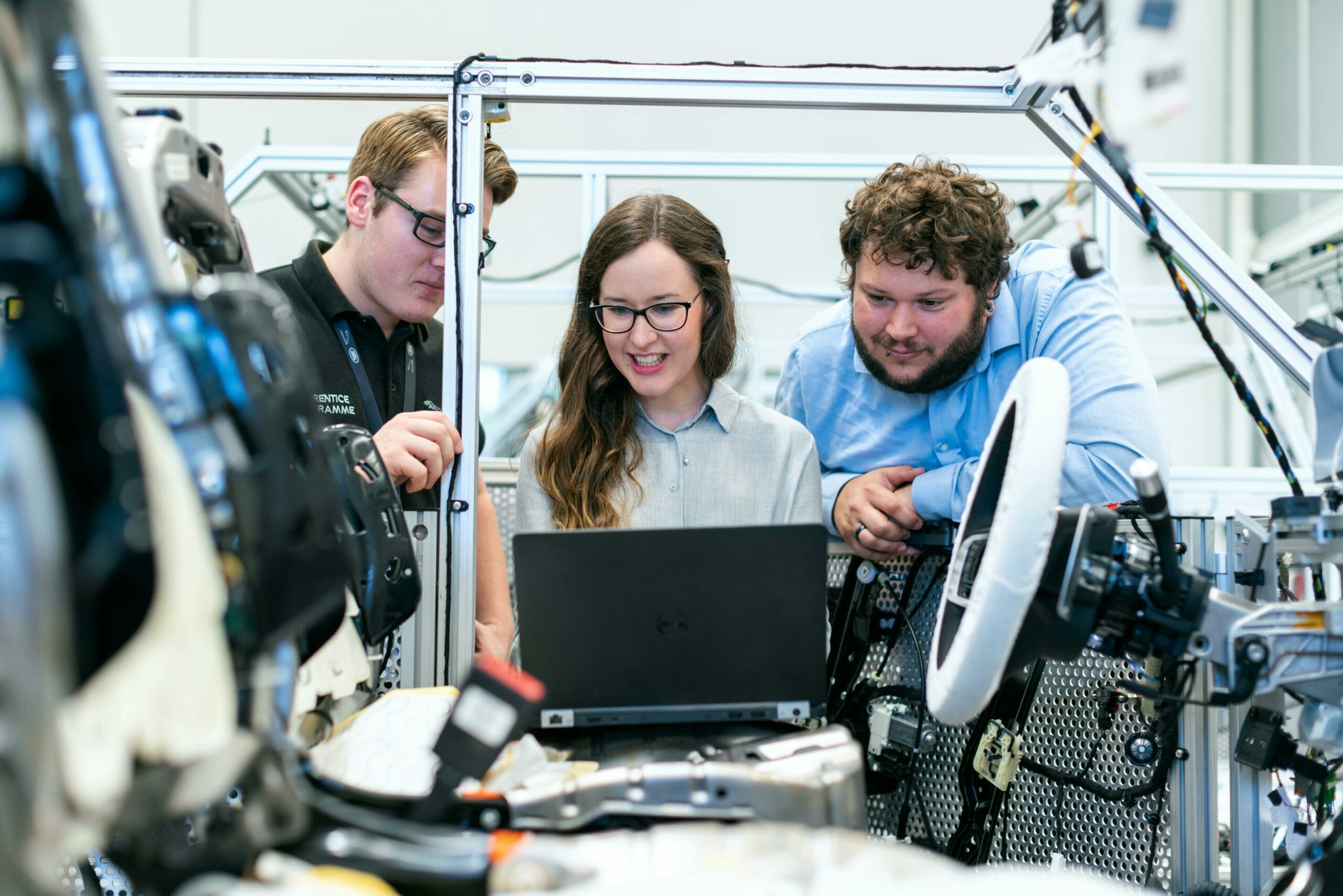

This standard first requires businesses to have a plan for achieving their goals. This must be included in their QMS along with ways to improve efficiency. Next, organizations must evaluate any factors that may impact the manufacturing process and the resulting product. Additionally, businesses must guarantee adequate workspaces, suitable tools, and skilled workers to support the manufacturing process. Lastly, businesses must continuously conduct internal audits to track and measure KPIs. This is to ensure their QMS is being properly implemented. Overall, ISO 9001’s goal is to improve product quality and customer satisfaction.

What is The IATF?

When diving into automotive compliance, it’s important to mention the IATF. IATF stands for International Automotive Task Force. It is the global automotive quality management system standard organization. Its main goal is to promote continuous quality improvement throughout the automotive supply chain. The most relevant IAFT standard to the current topic is IATF 16949. IATF 16949 is a QMS standard specific to the automotive industry. Its goal is to ensure quality and consistency across the automotive supply chain. What is unique about this regulation is it includes ISO 9001 requirements within its standards.

ISO 9001 vs. IATF 16949

What are the differences between ISO 9001 and IATF 16949? The first and most obvious difference is ISO standards are applied to all industries while IATF is specific to the automotive industry. Next, ISO 9001 standards focus on enhancing product quality and customer satisfaction, while IATF 16949 focuses on defining QMS requirements. Additionally, IATF 16949 includes CSRs while ISO 9001 does not. Both standards offer certification, but IATF 16949 necessitates compliance and has a much more rigorous process. In addition to this, ISO 9001 can apply to any operational location while IATF 16949 solely applies to sites that develop or service OEM auto parts. Both standards assess risks and aim to ensure consistency and efficiency throughout the manufacturing process.

ISO 9001 for Automotive Compliance

Why is ISO 9001 important to the automotive industry? It provides a framework for enhancing product quality and satisfying customer needs. This is relevant to automotive manufacturing because clients desire certain vehicle features. Some of these characteristics include technological advancements, safety features, and cost-effectiveness. When automotive manufacturers follow the ISO 9001 guidelines, they ensure high-quality automobile manufacturing, leading to satisfied consumers. Additionally, adhering to these standards creates transparency with the customer. For example, a company may publicly recall a part that does not meet the guidelines.

It is also important to note that although IATF 16949 is designed specifically for the automotive industry, it is not meant to be independent. This standard is made to accompany a QMS, while ISO 9001 is independent, focusing on satisfaction and efficiency. Let’s explore a few examples of how ISO 9001 applies to the automotive industry.

- Quality Improvement: ISO 9001 provides guidelines for improving QMSs, products, and services which can be applied to the entirety of the manufacturing process.

- Customer Satisfaction: Automotive suppliers utilize ISO 9001 to meet customer expectations by effectively communicating and continuously delivering high-quality products.

- Continuous Improvement: ISO 9001 encourages automotive companies to identify and resolve issues, increasing efficiency and reducing costs. This is vital in the competitive automotive industry.

- Risk Assessment: In addition to identifying efficiency issues, automotive manufacturers are also encouraged to identify risks such as disruptions and recall issues. This ensures safety and consistent product quality.

- Regulatory Compliance: It may seem redundant, but the automotive industry has many regulations manufacturers must follow, and ISO 9001 helps them stay within these guidelines, especially with ISO certification.

Benefits of ISO 9001 Certification in the Automotive Industry

There are many benefits to getting ISO 9001 certified in all industries, but especially in the automotive industry. First and foremost, getting ISO 9001 certification displays the quality of an organization. It is a globally recognized symbol that gives an automotive manufacturer an advantage over non-certified competitors. ISO 9001 certification not only encourages but requires organizations to identify and resolve efficiency issues. In addition to this, it requires organizations to identify risks and take preventative measures. Both of these requirements create a better product and ensure customer safety and satisfaction.

ISO 9001 certification also requires a company’s QMS to define its processes and set goals, once again increasing efficiency. Additionally, companies are required to document and measure their processes. This documentation acts as a guideline and ensures manufacturers comply with industry standards. This guideline is continuously altered to improve processes, as required by ISO 9001. In summary, ISO 9001 certification increases efficiency, resolves issues, and defines goals to put one automotive manufacturer above the rest.

How SPK Can Help You Get ISO 9001 Certified

The benefits of ISO 9001 certification may have you eager to get certified. So, how do you do it? The quickest and easiest way to get certified is to seek a consultant. SPK offers consulting for a wide range of compliance certifications, including ISO 9001. Our team has over 20 years of experience, offering unique insights to help you streamline your processes. We can ensure your products will quickly get to market while staying in-line with industry standards. If you would like to learn more about how we can help, contact our experts today.