As vehicle software complexity explodes, automotive manufacturers are pushed to accelerate to keep up. Suppliers must meet stringent safety and quality standards like ISO 26262 and ASPICE while keeping costs low. These quality standards are vital to success, as quality issues can ripple across the entire vehicle lifecycle. This leads to recalls, warranty claims, scrap, rework, and margin erosion. For many suppliers, fragmented processes, manual traceability, and disconnected systems cause 10% of the total cost of quality. Digital traceability changes that equation. When requirements, design, testing, and compliance are connected across hardware and software, suppliers gain the visibility needed to prevent quality issues instead of reacting to them post-launch.

PTC’s ALM and PLM Stack: Codebeamer and Windchill

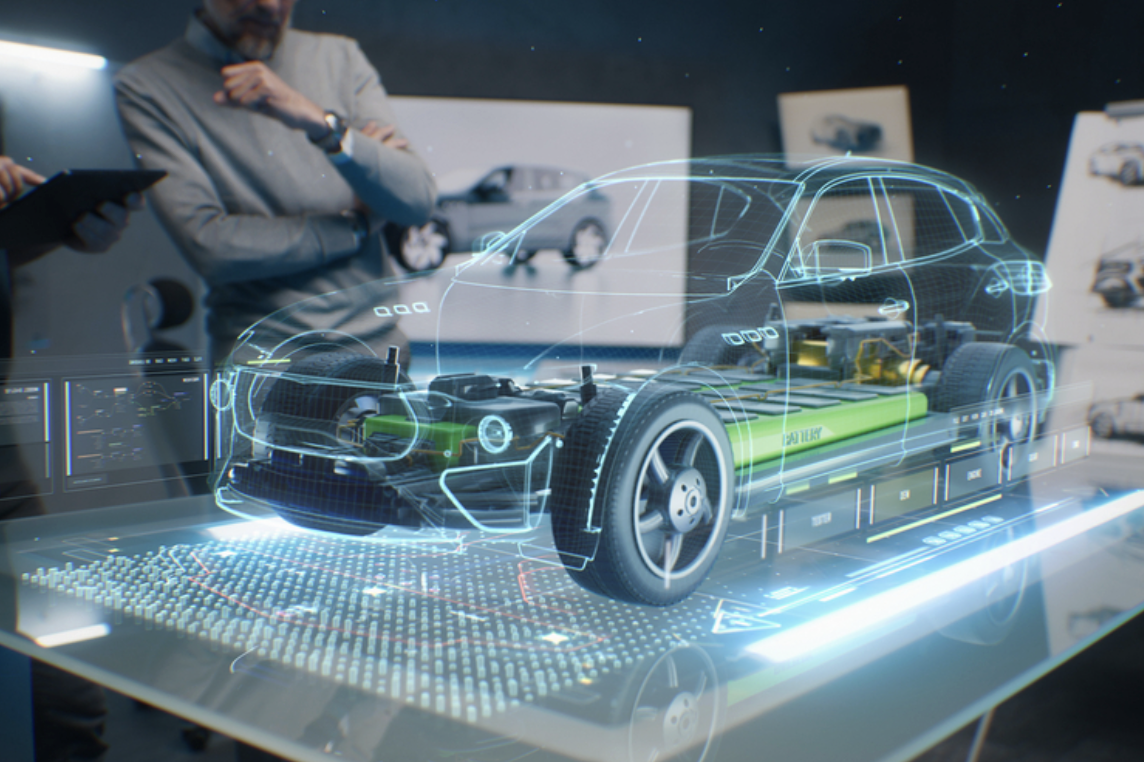

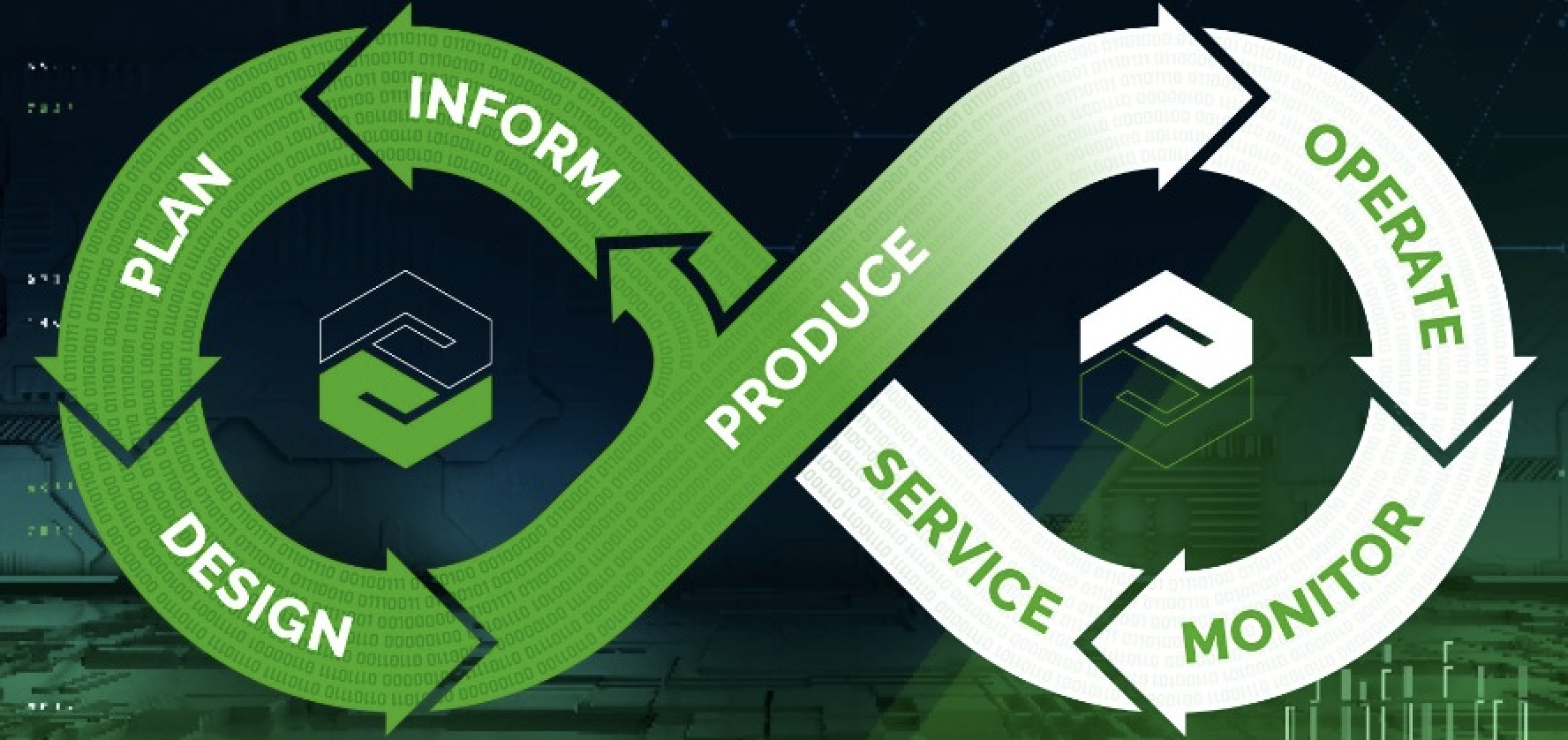

At the core of digital traceability is a connected lifecycle. PTC’s ALM and PLM stack brings this to life by unifying software, hardware, and product data from concept through service.

PTC Codebeamer is an enterprise-grade Application Lifecycle Management platform built to handle the complexity of modern automotive development. It manages requirements, risks, tests, and compliance artifacts in a single system, with full digital traceability across software and hardware domains. Codebeamer is purpose-built for regulated industries, making it a natural fit for ISO 26262, ASPICE, and other safety-driven frameworks.

PTC Windchill serves as the backbone for Product Lifecycle Management. Windchill provides a secure, centralized system of record for CAD data, BOMs, configurations, and documentation. It enables multi-CAD collaboration, workflow automation, and configuration management across global teams and suppliers.

Together, Codebeamer and Windchill create a unified product data foundation that connects requirements to design, design to manufacturing, and manufacturing to service.

Reducing Recalls, Warranty Costs, and Rework

Many of the cost drivers behind recalls and warranty claims trace back to the same root causes. The first being requirements changes that do not propagate downstream. This means software and hardware teams working in parallel without a shared view of risk. Another cost driver is when employees assemble manual compliance documentation too late in the process. Lastly, poor visibility into past designs that engineers can reuse leads to unnecessary rework.

Connected ALM and PLM directly address these issues. With centralized hardware and software requirements in Codebeamer, engineering teams can digitally validate designs earlier. Risks are identified and managed before engineers build physical prototypes. Automated traceability ensures that when a requirement changes, its impact on tests, designs, and compliance artifacts is immediately visible.

By integrating Codebeamer with Windchill, traceability extends beyond R&D into manufacturing and service. Quality issues identified during production or in the field can be traced back to specific requirements, designs, or software changes. This reduces scrap, rework, and the likelihood of widespread recalls. Just as important, regulatory compliance becomes a byproduct of daily work rather than a separate, manual effort. A centralized system of record allows users to generate automated reports and compliance files for standards like ISO 26262 and ASPICE. This eliminates weeks of manual documentation and reduces audit risk.

For Tier 1 and Tier 2 suppliers, this level of traceability has a measurable impact. Organizations with connected lifecycle management routinely see up to a 10 percent reduction in total cost of quality by preventing defects earlier, minimizing rework, and avoiding costly late-stage fixes.

PTC x SPK for Automotive Suppliers

While PTC’s ALM and PLM solutions are impressive, technology alone does not deliver these results. The real value comes from how systems are integrated, configured, and adopted across engineering, quality, and supplier networks. SPK and Associates plays a critical role in helping automotive suppliers realize the full value of PTC’s ALM and PLM stack. SPK works with Tier 1 and Tier 2 organizations to design and implement end-to-end traceability strategies that align with real-world development and compliance needs.

This includes integrating Codebeamer and Windchill into a single digital thread, aligning requirements and change management processes across hardware and software teams, and extending collaboration securely to suppliers. We help suppliers reduce risk while accelerating development, and the results are tangible. Automotive organizations leveraging connected lifecycle management with our guidance have achieved measurable improvements, such as a 122% return on investment within an 11 month payback period.

Automotive Traceability with Windchill and Codebeamer

The cost of quality is no longer something automotive suppliers can manage with spreadsheets and disconnected tools. As compliance requirements become more stringent, engineers must integrate quality into the lifecycle from day one. Digital traceability, enabled by a connected ALM and PLM stack like Codebeamer and Windchill, gives automotive suppliers the visibility and control they need. When combined with experienced consulting support from SPK and Associates, this approach transforms quality from a cost center into a competitive advantage. For automotive suppliers navigating margin pressure, global complexity, and accelerating innovation cycles, controlling the cost of quality starts with connecting the lifecycle. Contact our experts today to see if PTC products align with your business goals.