For companies in the highly regulated medical device industry, speed to market is directly tied to patient impact and competitive advantage. However, many MedTech organizations continue to struggle with long, unpredictable New Product Introduction (NPI) cycles. Extended timelines are often due to manual documentation, disconnected systems, and inefficient handoffs between engineering, quality, and manufacturing teams. These challenges delay approvals, increase costs, and slow innovation. Let’s explore the most common causes of NPI delays and how digital thread technologies and modern platforms can help organizations reduce NPI cycle time by up to 20%.

Understanding the Root Causes of NPI Delays

Across MedTech organizations, excess NPI cycle time is rarely caused by a single issue. Instead, it stems from systemic inefficiencies that compound over the product lifecycle. Let’s dive into the most common causes of NPI delays.

Manual and Fragmented DHF Management

Many companies still rely on spreadsheets, shared drives, and manual processes to manage Design History Files (DHF). This requires extensive tracking, version control, and document compilation during audits and submissions. As products grow more complex, manual DHF management becomes unsustainable and error-prone, increasing the risk of rework and regulatory delays.

Lack of Synchronization Between Design and Manufacturing

When design changes are not automatically synchronized with downstream teams, manufacturing and quality often operate on outdated information. This leads to misaligned prototypes, delayed validations, and costly change requests late in development. Without a connected digital backbone, engineering and operations teams struggle to stay aligned.

Undetected Design and Requirements Issues

Changing requirements, evolving standards, and incomplete traceability can cause issues to remain hidden until late-stage testing or pilot production. These late discoveries force redesigns, repeat testing, and schedule extensions that significantly impact NPI timelines. Check out the problem with late-stage changes in this video:

Limited Design Reuse and Redundant Part Creation

Poor visibility into existing designs and components often results in teams recreating parts that already exist elsewhere in the organization. This lack of reuse increases engineering effort, complicates validation, and expands regulatory documentation, all of which slow time to market.

How the Digital Thread and AI Reduce NPI Cycle Time

Leading MedTech organizations are addressing these challenges by building a unified, intelligent product lifecycle environment powered by digital thread technologies and AI.

AI Built Into the Product Lifecycle

Modern PTC solutions embed AI directly into product development and lifecycle management. These intelligent capabilities help teams:

- Automate regulatory documentation

- Identify compliance gaps earlier

- Surface risks and inconsistencies

- Accelerate root cause analysis

AI-powered agents and analytics reduce manual effort and improve decision-making throughout the NPI process.

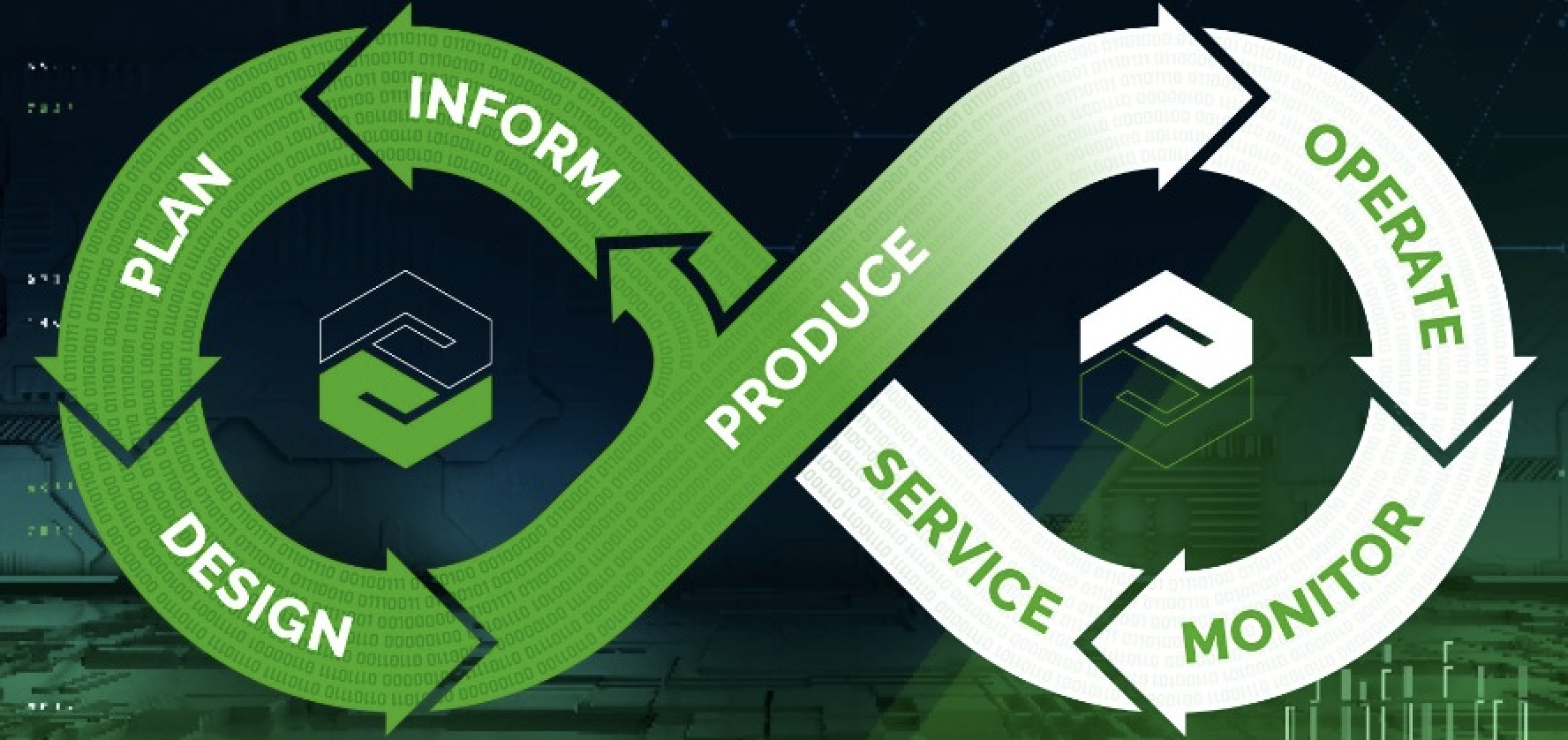

A Product Data Foundation from Requirements to Service

At the core of accelerated NPI is a unified product data foundation. This foundation connects:

- Requirements and risk management

- CAD and simulation data

- Change management workflows

- Manufacturing and service information

With a single source of truth, teams gain real-time visibility into product status, dependencies, and compliance readiness.

Open, SaaS-Enabled Connectivity

PTC’s SaaS-enabled platforms support open integrations across the product ecosystem, connecting PLM, CAD, ERP, MES, QMS, and ALM systems.

This openness enables:

- Faster system updates and scalability

- Improved security and governance

- Easier data sharing across partners and suppliers

- Reduced IT overhead

By leveraging SaaS and open APIs, organizations can modernize without disrupting existing operations.

NPI Challenges and How PTC and SPK Solve Them

Industry data shows that up to 20% of excess NPI cycle time is caused by avoidable process inefficiencies. Here is how modern digital thread solutions address them.

AI-powered Regulatory Management

Manual compliance processes require extensive tracking, validation, and compilation, slowing regulatory submissions. PTC offers AI-powered regulatory management and centralized compliance databases. These tools automate DHF generation, reporting, and audit preparation. Teams can produce submission-ready documentation in hours instead of weeks.

Traceability

When uncoordinated design changes disrupt downstream teams and delay validation, teams need end-to-end traceability and integrated change management. These features connect R&D, manufacturing, quality, and service. Every change is evaluated for regulatory, manufacturing, and supply chain impact before execution.

Early Design Changes

Undetected problems in design or requirements lead to inefficient prototyping and production delays. Advanced simulation and optimization tools, powered by Creo and Windchill, use 3D models as the authoritative source of truth. Teams can validate manufacturability, performance, and compliance early in development.

Part Reuse

Poor component visibility leads to unnecessary duplication and validation effort. Parts and assembly rationalization capabilities in Windchill provide visibility into shared components across product lines. Engineers can quickly identify approved, validated designs for reuse.

Achieving 20% Faster NPI with PTC and SPK

PTC customers leveraging digital thread technologies consistently achieve up to 20% faster NPI cycle times by aligning people, processes, and data across the lifecycle.

SPK and Associates helps MedTech organizations realize these benefits by delivering:

- Automated design reuse frameworks

- Connected R&D-to-Manufacturing workflows

- Integrated PLM, CAD, QMS, and ALM environments

- AI-assisted compliance and documentation solutions

- Regulatory-ready digital thread architectures

Using platforms such as Creo and Windchill, SPK builds scalable, compliant ecosystems that accelerate approvals.

Accelerating Innovation in MedTech

Achieving reduced NPI cycle times is possible with connected systems, intelligent automation, and unified data. Replacing manual processes with AI-powered regulatory management, synchronizing design and manufacturing through digital thread technologies, and enabling systematic reuse can cut cycle times by up to 20%. Contact our team today to discover how PTC’s intelligent, SaaS-enabled platforms can bring safer, more innovative products to market faster in the medical device space.