Looking for a great out-of-the-box solution for a Quality Management Systems (QMS) that exceeds the compliance requirements for FDA? MasterControl could be a good option for you. It even includes the stringent guidelines outlined in 21 CFR Part 820. Let’s take a deeper look at MasterControl QMS and how you can maximize its potential with a SolidWorks integration.

MasterControl QMS Key Features

- End-to-End FDA Compliance: MasterControl’s out-of-the-box QMS encompass all compliance items necessary for FDA approval. Therefore, it offers a holistic solution for businesses navigating regulatory compliance.

- Automated Regulatory Compliance: The system takes the burden off critical quality processes, such as document management, training, quality events, supplier management, and quality audits. Furthermore, automation ensures accuracy, efficiency, and peace of mind.

- Connected QMS Platform: Digitizing and integrating quality data across the entire product life cycle transforms it into a business-wide asset. Additionally, this interconnected approach empowers change and improvement, setting the stage for enhanced operational efficiency.

- Thorough Document Management: MasterControl’s QMS goes beyond mere document storage. Instead, it facilitates collaboration, improves decision-making, and accelerates time to market by automating core business processes related to document management.

- Cloud-Based Quality: MasterControl’s cloud-based QMS software not only digitizes but consolidates formerly paper-based data and documentation. And, frequent software updates enable continuous improvement in quality and compliance processes.

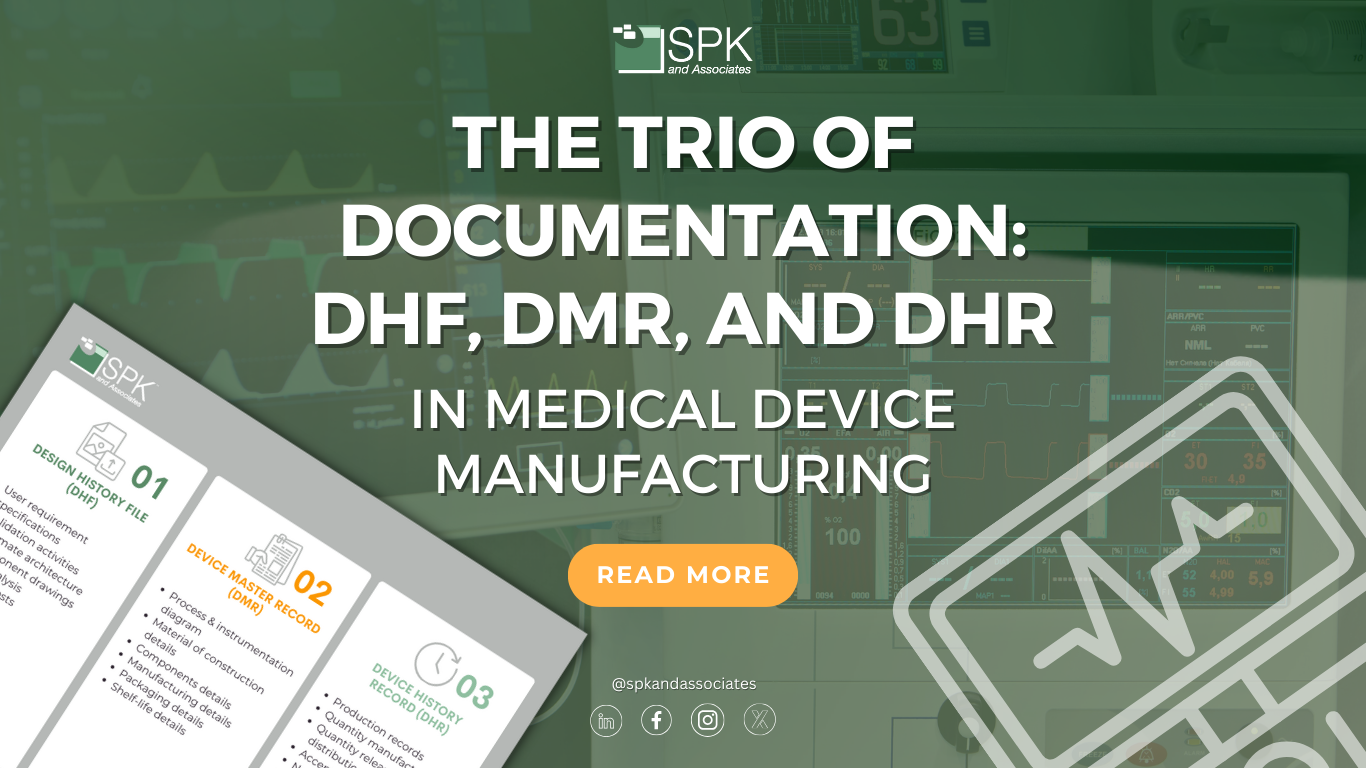

Learn about DHR, DHF and DMR medical device documentation.

Integrate MasterControl and SolidWorks PDM

If you are one of the businesses immersed in engineering and design, SPK’s solution ‘MasterManager’ connects SolidWorks PDM and MasterControl’s QMS. This integration automates data transfer and enhances accessibility and accuracy of engineering documents, creating a seamless business system.

Our MasterManager Customer Success Story

Here’s a quick overview of the success one of our medical device customers achieved using the MasterManager solution. You can also read the full case study here.

- Challenges in Medical Device Manufacturing: The client, operating in a highly regulated industry, faced challenges in maintaining engineering productivity and quality. With MasterControl’s QMS already in place, and SolidWorks PDM managing CAD design data, the need arose to bridge the gap between the two systems.

- The MasterManager Solution: Recognizing this gap, SPK, with its deep expertise in API programming and a longstanding partnership with MasterControl, developed MasterManager. This automated connector seamlessly transfers engineering documents from SolidWorks PDM to the corresponding records in MasterControl, eliminating the need for tedious manual processes.

- Smart Engineering Solutions: Our approach was tailored to the client’s specific needs, ensuring that the solution reflected the company’s requirements, input, and values. With over 20 years of experience in API programming systems, our team ensured the quality and time efficiency of the project.

- Achieving Seamless Integration: MasterManager’s configurable nature allows users to determine parameters for comparisons and data updates. This not only eliminates manual processes but establishes a single source of truth for reference, ensuring the quality of data and simplifying tracking.

- The results: Upon implementing MasterManager, the medical device manufacturer immediately saved $42,000 per year in operational engineering expenses. This not only presents immediate cost reductions but positions the company for exponential savings as it grows. Additionally, creating a single source of truth between systems eliminates time-consuming cross-checks, freeing up engineers for innovation and revenue-generating efforts.

Discover how you can improve your trend analysis using the right QMS.

Want To Learn More About MasterControl Or MasterManager?

MasterControl provides a great out of the box solution to help you achieve FDA compliance. And, as a MasterControl partner with a few nifty integration solutions up our sleeves, we can help you get the best out of the MasterControl QMS. Connect with us to learn more.