Transitioning from SolidWorks to Creo can be a game-changer for many engineering teams seeking advanced capabilities and streamlined workflows. However, it often comes with its own set of challenges and considerations. That’s why we’re sharing an essential roadmap to successfully migrate from SolidWorks to Creo.. We’ll cover the critical aspects of this consolidation process. For example, understanding key feature differences as well as harnessing the full potential of Creo’s robust toolset. Get ready to elevate design, streamline data, explore integrated power – this guide kickstarts your successful transition journey.

What is SolidWorks?

SolidWorks is a powerful computer-aided design (CAD) and computer-aided engineering (CAE) software. It is widely used across various industries for 3D modeling, assembly, and drafting. Plus, it’s renowned for its user-friendly interface and extensive feature set. Essentially, SolidWorks enables designers and engineers to create detailed 3D models and mechanical drawings with precision and efficiency. It’s particularly popular in sectors like manufacturing, automotive, aerospace, and product design. That’s due to its robust simulation capabilities and compatibility with a wide range of file formats for seamless collaboration.

What is Creo?

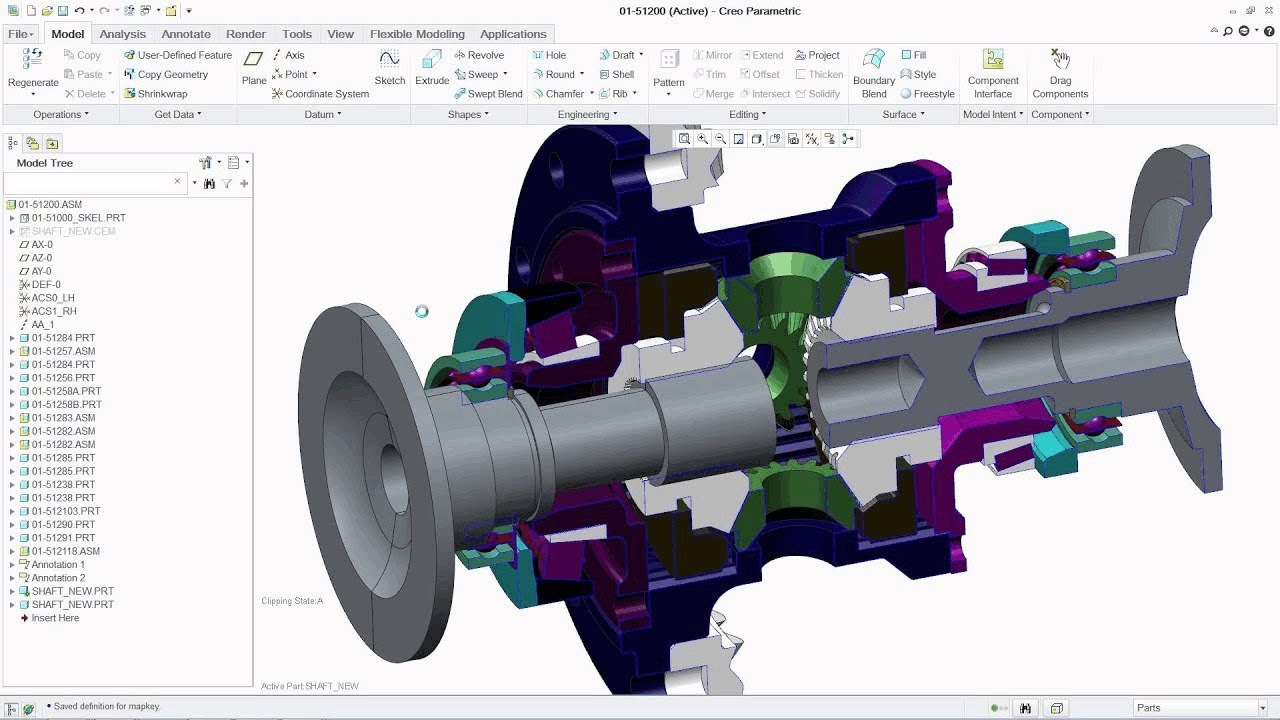

Creo is developed by PTC. Basically, it is a comprehensive suite of CAD/CAM/CAE software offering advanced tools for:

- 3D product design.

- Simulation.

- Manufacturing.

Distinguished by its ability to handle complex engineering challenges, Creo is highly regarded for its parametric and direct modeling capabilities. Additionally, it provides a scalable approach to product development. Furthermore, it is extensively used in industries such as high-tech electronics, automotive, and industrial machinery. Fundamentally, its powerful features support an integrated approach to product design, from conceptualization to manufacturing.

Why Migrate from SolidWorks to Creo?

Before we get into how to migrate from SolidWorks to Creo, you may be trying to understand the “why” of a migration. So, we’ve compiled a few examples below that collectively have been drivers to move to Creo.

Key Differences between SolidWorks and Creo

SolidWorks and PTC Creo, while both prominent in the CAD software domain, cater to different needs and offer distinct experiences.

- SolidWorks is often praised for its intuitive interface and ease of use, making it a popular choice for quick design tasks and for users who require a straightforward, efficient CAD solution.

- Conversely, PTC Creo is known for its comprehensive feature set and robust parametric capabilities. Typically, these are well-suited for handling complex, large-scale engineering projects. For example, ones requiring detailed attention to the intricacies of design and simulation.

- Furthermore, Creo offers greater scalability and advanced features in areas such as additive manufacturing and IoT integration, which are less pronounced in SolidWorks.

These differences make SolidWorks ideal for small to medium-sized projects or businesses. Alternatively, Creo is often the choice for larger organizations dealing with more complex product development challenges.

Exploring Technology Advancements of SolidWorks and Creo

While SolidWorks has primarily focused on AR/VR Exporter technology in recent years, its future seems to pivot towards the 3D Experience Platform. In contrast, Creo has significantly expanded its capabilities in the past 24 months. For example, introducing features like:

- Generative Design Optimization.

- Multibody.

- Real Time Analysis in various domains.

- Advanced Additive Manufacturing.

- And others.

It’s important to assess if these developments align with your current and future project needs.

The 5 Steps To Consider Before You Migrate From SolidWorks To Creo

Evaluate Support and Software Utilization

Reflect on the value derived from your SolidWorks support. Does your SolidWorks VAR provide adequate assistance? Or, are you finding more self-reliance? Next, consider if the absence of recent significant updates in SolidWorks affects your decision to upgrade to newer versions.

Is There A Lack of Value in 3DExperience SolidWorks?

Many SolidWorks users initially chose it for its simplicity as a CAD tool. So, moving to the 3DExperience platform represents a significant shift to a SaaS platform. It’s crucial to determine if this transition aligns with your organizational objectives and operational preferences.

Also, many features in the 3DExperience platform are missing in comparison to SolidWorks installed on a Windows workstation. Furthermore, 3DExperience Solidworks currently doesn’t support all Solidworks add-ins (like CAM). This is another reason clients have been reluctant to move to 3DX. While 3DExperience Solidworks comes with cloud PLM included, it is not required to use. Plus, some engineers also feel having the tools bundled is a bit overwhelming.

Address SolidWorks Stability Concerns

The stability and frequent crashes of SolidWorks are well-known. Often, this leads to substantial productivity losses. So, analyze how these issues impact your daily operations and whether a more stable alternative like Creo might enhance efficiency.

Consider Workflow Integration and Remote Access Challenges

Additionally, you’ll want to investigate the efficiency of your current workflow with SolidWorks. Does remote access pose challenges? Are third-party plugins necessary for daily operations? Evaluate SolidWorks PDM limitations in workflow management and data accessibility, comparing its efficiency to Creo’s Windchill solutions.

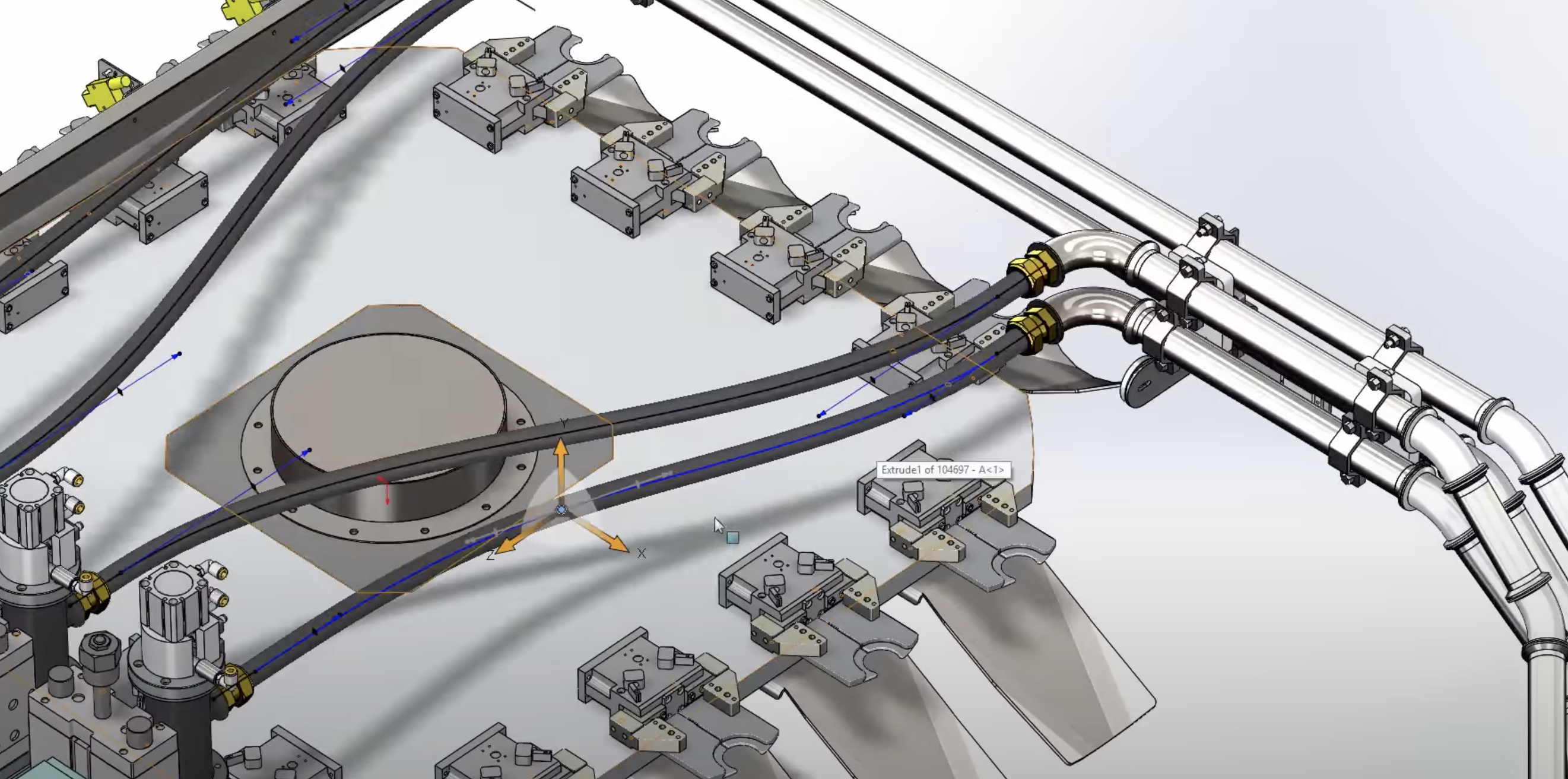

Handling Geometry and Design Structuring in Creo vs. SolidWorks

Users often experience issues with geometry rebuilding and design tree reordering in SolidWorks. However, Creo offers enhanced robustness and reliability in these aspects, facilitating smoother design processes.

5 Step Roadmap To Successfully Migrate From SolidWorks to Creo

There are several important steps to take into consideration to migrate from SolidWorks to Creo. Below, we’ve covered them in five steps. Obviously, the amount of work inside of all of them can take weeks or months. However, this will give you a roadmap to success. You can also find more information on how to migrate from SolidWorks to Creo This process is mentioned here.

Step 1: Preparing for the Transition

Pre-assessment

Assessing your current SolidWorks environment is a critical first step in the transition to PTC Creo.

- Complete a thorough examination of your existing workflows, design processes, and the complexity of projects handled in SolidWorks.

- Understand the extent to which SolidWorks is integrated into your current operations. This includes an evaluation of the file types, custom tools, and third-party add-ons in use.

- Analyze the hardware capabilities and the training levels of the team members who operate SolidWorks will provide valuable insights.

This evaluation pinpoints needs and potential challenges for a smooth and efficient migration to Creo.If you’re concerned about the current hardware capabilities of your engineers, you can review SPK vCAD in order to support an on-demand environment for your design engineers.

Stakeholders and Engagement

Beyond file types, tools, and workflows, recognizing key stakeholders and establishing realistic goals and timelines are crucial for SolidWorks to Creo transition success.

- Stakeholders typically include team leads, CAD managers, IT personnel, and end-users. For example, designers and engineers. Their input is crucial for understanding different perspectives and needs.

- Furthermore, this aids in creating a comprehensive and inclusive transition plan.

Set Realistic Goals To Migrate From SolidWorks To Creo

Setting realistic goals is crucial when undertaking a CAD data migration project. Often, there’s a misconception among clients that they should transfer all their CAD data to Creo Parametric, expecting it to mirror features exactly as in their existing system. However, it’s important to understand that the technology for an automatic, full-feature migration simply doesn’t exist.

- Setting realistic goals involves defining clear objectives for the transition, such as improved design capabilities or enhanced collaboration efficiencies.

- Timelines should be carefully planned, considering the complexity of the migration, training requirements, and potential disruptions to ongoing projects.

- Striking a balance between ambition and feasibility, incorporating flexibility, ensures a transition aligned with organizational goals, both immediate and long-term. Migrating every piece of data and feature can be an unnecessary drain on resources. Creo Parametric allows users to open and view CAD data from other systems without the need for full migration. Consider the time and cost savings when you don’t migrate all your CAD data, especially for products that are no longer in active use.

Also, it’s essential to recognize migrated CAD data will not replicate the feature content from the original system. However, this shouldn’t be a concern; in fact, it’s an opportunity. With Creo, you have the chance to develop superior features moving forward. Its Flexible Modeling functionality enables end users to adapt and refine geometry more effectively, opening up new avenues for design innovation.

Step 2: Evaluate Your CAD Needs

In this step, you’ll want to determine what needs migrated, and what data can be avoided to be scoped in the migration. You can ask questions like the following to determine what is in scope versus out of scope for when you migrate from SolidWorks to Creo. The list of questions below should help get you started:

- Does your industry or business require a record of all retired products?

- How complex is the CAD data?

- How long are your product development cycles? ( For example, do your projects last months, quarters, or years?)

- What stage of the design or product lifecycle are they in?

- If early in the design or product stage, migrate early would be beneficial to use Creo Parametric to build a more robust design?

- If late in the design or product stage, it may be easier to finish the design in the CAD software?

- Will there be minimal or dramatic changes to product designs in the future?

- Are there products that are retired or will have no changes made in the future?

Step 3: Determine Migration Strategy

In this state, there are essentially three options to migrate from SolidWorks to Creo. We have listed them below along with the advantages and disadvantages of each.

Complete Redesign in Creo Parametric

This involves starting from scratch to redesign all parts and assemblies using Creo Parametric.

| Pros | Cons |

|

|

Feature-by-Feature Translation Approach

Employ a specialized software or a service partner to map out how to transition parts and assemblies, comparing the features of your existing CAD software with those of Creo Parametric.

| Pros | Cons |

|

|

Selective Modification in Creo Parametric

Utilize Creo Parametric’s Unite technology to open and modify non-PTC data as necessary.

| Pros | Cons |

|

|

Note: When migrating 3D drawings, associated 2D drawings do not automatically transfer. This is a common limitation across various platforms. However, Creo’s Legacy Migration Extension offers tools to re-link 3D models with their corresponding 2D drawings, mitigating this issue.

Step 4: Determine Cut Over Date(s) To Migrate From SolidWorks To Creo

Many companies opt not to abandon their current CAD systems instantly, choosing instead to run them concurrently with Creo. Alternatively, your organization might prefer a complete shift to Creo to fully leverage its advanced capabilities. So, as you strategize the phasing out of your existing CAD system, determine the implications to these key considerations:

- Have you marked a calendar date when your team will switch exclusively to using Creo Parametric for all projects?

- If you plan to maintain your current CAD software, how will you allocate different types of projects or tasks between the old system and Creo Parametric?

- Do you intend to complete ongoing projects using your current CAD system and reserve Creo Parametric for new initiatives?

- Is there a plan in place for initiating all new product designs strictly in Creo Parametric?

Step 5: Verify PLM System Connections

Many of our own clients employ product lifecycle management (PLM) or enterprise data management systems for overseeing their CAD data. If you do the same, reflect on the current methods your organization employs for CAD data management. Then, consider how transitioning to Creo might alter this:

- Does your existing approach to data management seamlessly integrate with Creo Parametric’s capabilities?

- Might there be a necessity to revise or enhance your data management strategy to complement Creo Parametric?

- Are you considering an upgrade to your PLM system to align with PTC’s Windchill PLM solution?

Results of Migrating from SolidWorks to Creo

The results of a migration from SolidWorks to Creo can be summed up in a few examples. The client names below have been obscured due to the sensitivity of the technology being used. However, we have received permission to share the statistics and quotes below.

Background: Multinational corporation operating mainly in robotics, power, heavy electrical equipment, and automation technology.

Challenge: Users on Solidworks, NX, Windchill,SAP, and Teamcenter

Solution: Worldwide standardization for design and simulation tools

Results: 100% decision for Creo – 500 users migrated in 2 years

Background: Multinational, half a billion dollar manufacturer of childcare products including car seats, push chairs and high chairs.

“Our company recently made a strategic decision to standardize on PTC Creo. Our stroller line was previously designed using SolidWorks, but after evaluating PTC Creo, it was a ‘no brainer’ to make the switch.”

Background: Multinational computer manufacturer with a niche design.

“PTC Creo is an incredibly stable program with an engineering focused and user-friendly interface. It has solved the issues that SolidWorks struggles with when working on complex assemblies and parts.”

Next Steps

Migrating from SolidWorks to Creo presents a strategic opportunity to harness advanced capabilities and achieve more streamlined design processes. Our guide has shed insight on the compelling reasons to make this shift, outlined a clear roadmap, and illustrated real-world successes. Embracing Creo not only signifies a step towards enhanced productivity but also opens doors to innovative design possibilities. Remember, the journey from SolidWorks to Creo, while demanding careful planning and execution, is a pathway towards improving your design strategy.

If you need support to successfully migrate, our SPK team are ready to help.