In the fast-paced world of product design, taking advantage of the best tools available can give your business a competitive advantage. PTC’s Creo is already an incredible CAD tool, but the Creo Ansys Simulation Advanced extension takes your simulation capabilities to the next level. Let’s explore the amazing capabilities of this extension.

What is Creo Ansys Simulation Advanced?

PTC Creo offers two extensions allowing users to integrate Ansys’ advanced capabilities into their CAD design. Ansys is a simulation software suite used to simulate product performance under various conditions. The Creo Ansys Simulation offers thermal, structural, and modal analyses to test designs under differing conditions. The Advanced extension offers these capabilities and more. Let’s explore the added features of Creo Ansys Simulation Advanced.

Capabilities of Creo Ansys Simulation Advanced

Multiphysics Studies

Creo Ansys Simulation Advanced allows users to run multiphysics studies. This means users can simultaneously run multiple studies such as structural analysis and thermal analysis together to model thermal expansion. This feature enables users to simulate all kinds of conditions, ensuring their design is well-tested before production. It is especially important to test conditions such as temperature when working in industries like aerospace and automotive, where temperatures can drastically change.

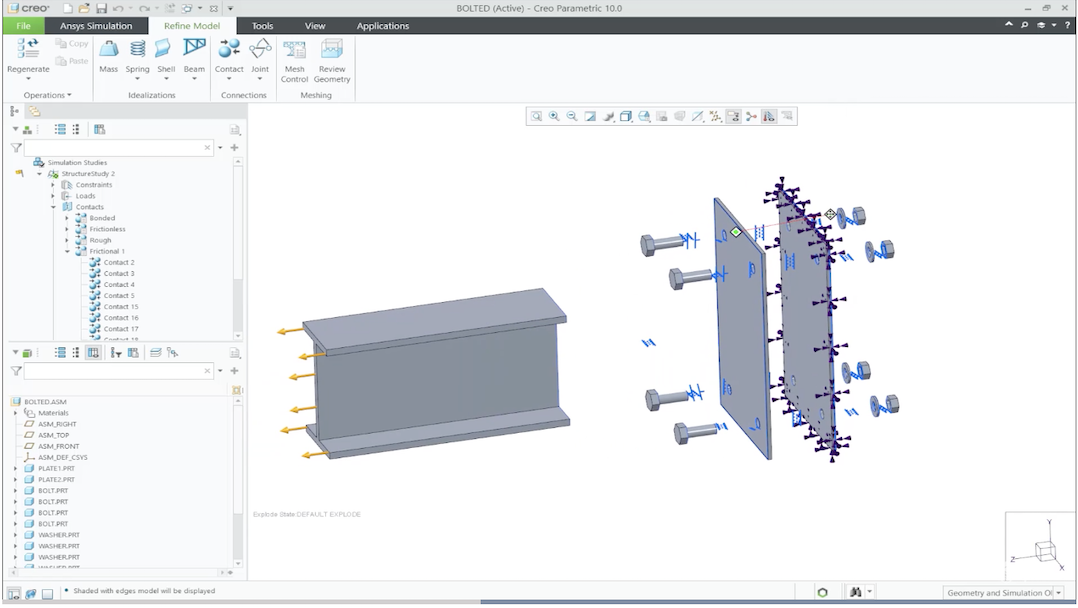

Nonlinear Contact and Material Modeling

In addition to multiphysics studies, the Creo Ansys Simulation Advanced extension offers nonlinear contact modeling. This type of simulation enables designers to study how two or more parts interact when they come in contact with each other when the deformation is not linear to the force applied. For example, coming in contact may cause an unpredictable amount of friction or damage to either piece. The Advanced simulation allows users to accurately simulate frictional, frictionless, and rough connectivity scenarios.

Furthermore, the Advanced extension offers nonlinear material modeling. This allows users to simulate deformations in three different types of nonlinear materials. These materials are Neo-Hookean hyperelasticity, linear orthotropic elasticity, and bilinear plasticity. This allows you to accurately predict how rubber-like materials, composites, or metals that experience plastic deformation will perform under various conditions.

Benefits of Integrating Simulation into Your Workflow

Utilizing Creo Ansys Simulation Advanced integrates simulation capabilities directly into your product development workflows. This saves time and allows feedback to be integrated into the design process. Additionally, it helps catch issues early to prevent late-stage design changes. Lastly, it saves money by avoiding costly mistakes and improving product quality for consumers.

Implementing Creo Ansys Simulation Advanced

The extensive features of Creo Ansys Simulation Advanced provide new ways to enhance your team’s design capabilities. If you are interested in creating more accurate simulations, leading to better products and faster delivery, SPK can help. Contact our experts to learn more about how you can implement the Advanced extension today.